Fleet downtime refers to periods when vehicles or equipment within a fleet are not operational and cannot be used for their intended purposes. This can happen due to various reasons, including maintenance, repairs, accidents, or other operational challenges.

Downtime translates directly into financial losses. On average, each vehicle’s downtime can cost a fleet between £350 to £595 per day, and these costs accumulate rapidly.

How can you reduce fleet downtime?

Over the past 8 years, our fleet management software developers have perfected their craft by creating custom software solutions tailored to the specific needs of various fleets and we want to share some of the top strategies we’ve discovered for reducing fleet downtime effectively.

And if you have any questions, you can always reach out to us via info@volpis.com. We would be happy to answer all your questions, create a customized system for managing your fleet, or add new features that would help you minimize your fleet downtime.

How to reduce fleet downtime? The best ways to reduce vehicle downtime in 2024

Let’s explore some of the most effective strategies that can help you reduce fleet downtime. Keep in mind that robust fleet management software helps implement and manage all these strategies efficiently.

1) Maintenance and repair strategies

Maintenance and repair are among the primary concerns and reasons for fleet downtime. These critical factors significantly impact operational efficiency, leading to potential delays in service and increased costs. Addressing these issues promptly can help in minimizing idle time and maintaining consistent fleet performance.

- Conduct regular vehicle inspections

Routine vehicle inspections detect early signs of wear and potential problems, preventing unexpected failures. By identifying issues during these checks, fleets can schedule repairs at convenient times, avoiding emergency breakdowns.

By continuously monitoring vehicle health statuses, managers can ensure prompt maintenance and minimize unexpected breakdowns, thus reducing fleet downtime and maintaining operational continuity.

- Conduct regular vehicle inspections

Routine vehicle inspections detect early signs of wear and potential problems, preventing unexpected failures. By identifying issues during these checks, fleets can schedule repairs at convenient times, avoiding emergency breakdowns.

By continuously monitoring vehicle health statuses, managers can ensure prompt maintenance and minimize unexpected breakdowns, thus reducing fleet downtime and maintaining operational continuity.

- Utilize telematics systems

By harnessing real-time data on vehicle health and performance, you can detect potential issues before they escalate, enabling timely intervention to prevent breakdowns.

Telematics technology empowers managers to schedule maintenance effectively, ensuring that vehicles remain operational and downtime is minimized.

- Conduct preventive maintenance

Another approach is preventive maintenance. The difference between preventive and predictive maintenance software lies in their approach to maintenance scheduling and problem detection. In a nutshell, preventive maintenance software relies on predefined schedules, while predictive maintenance software uses real-time data to predict maintenance needs.

PepsiCo implemented preventive maintenance across its delivery fleet, resulting in an average reduction in unplanned downtime of over 20% while also increasing the efficiency of its supply chain by up to 10%.

- Conduct predictive maintenance

A proactive approach to maintenance—identifying and addressing issues before they escalate—significantly extends vehicle lifespan and reduces unplanned downtime.

Predictive maintenance employs advanced technologies like IoT sensors, artificial intelligence (AI), and machine learning to analyze a wide range of vehicle parameters that can indicate potential problems before they become serious. Some of these parameters include:

- Engine temperature: Overheating can be a sign of problems like coolant leaks, blocked radiators, or failing water pumps.

- Vibration levels: Increased vibration can indicate issues such as wheel alignment problems, tire imbalance, or drivetrain malfunctions.

- Oil conditions: Sensors can monitor oil level, oil temperature, and even the presence of metal fragments in the oil, which can indicate engine wear and tear.

- Battery condition: Monitoring the battery condition can prevent a sudden failure that could lead to vehicle downtime.

- Brake performance: Sensors can assess brake pad wear and tear and detect any decrease in brake fluid levels.

- Exhaust emissions: Excessive emissions can indicate engine problems or a failing catalytic converter.

According to a report by Deloitte, predictive maintenance increases productivity by 25%, reduces breakdowns by 70%, and lowers maintenance costs by 25%.

The obvious benefit of predictive maintenance is that it maximizes runtime. Repairs can be carried out just before a breakdown. Also, it can assist purchase departments by predicting which spare parts will be needed at which point in time.

- Use AI to analyze data about your fleet downtime

Often, downtime stems from overlooked issues or driver behaviors. Utilizing a robust data analysis system can pinpoint these issues effectively. Relying solely on drivers to report issues leaves room for oversight, as drivers may overlook dashboard lights or diagnostic trouble codes (DTCs) amidst their other responsibilities. Implementing real-time monitoring systems allows fleet managers to proactively identify and address potential issues before they escalate.

With the ability to analyze vast amounts of data, artificial intelligence and machine learning offer unprecedented opportunities to reduce vehicle downtime. These technologies in fleet management systems can analyze complex data, learn from patterns and trends, and make autonomous decisions.

Consider implementing regular data analysis routines. This proactive approach helps identify and address issues promptly, ensuring smoother fleet operations. By delving into fleet data, you can uncover patterns indicating overlooked downtime factors or problematic drivers. This insight enables targeted interventions to minimize downtime effectively.

- Streamline workshop management

Efficient workshop management plays a key role in reducing downtime. Delays often stem from inefficient service processes rather than the repairs themselves.

Streamlining repair processes and ensuring effective communication between teams accelerates turnaround times. This includes optimizing inventory management to have necessary parts available and reducing waiting periods for repairs.

You can optimize workshop management by implementing efficient scheduling, ensuring quick access to necessary parts, and fostering communication between maintenance, operations, and administrative teams to prevent delays.

- Maintain meticulous records of vehicle performance

Rather than just maintaining records, prioritize a proactive approach by scrutinizing vehicle performance data to anticipate and prevent potential issues.

It’s important to ensure comprehensive documentation including maintenance records, driver logs, fuel consumption data, and vehicle inspection reports. Delve deeper into this data, utilizing advanced vehicle monitoring systems to identify patterns and pre-emptively address emerging concerns.

You can identify recurring issues or wear patterns through a thorough analysis of historical data and adjust maintenance intervals accordingly.

- Optimize schedules

Coordinating schedules between drivers and maintenance staff is crucial for preventing conflicts. Implementing software tools that automate scheduling processes can streamline this coordination, ensuring tasks are completed promptly and minimizing downtime.

By streamlining scheduling operations, fleet managers can maintain a seamless workflow, ultimately reducing downtime and maximizing fleet ROI.

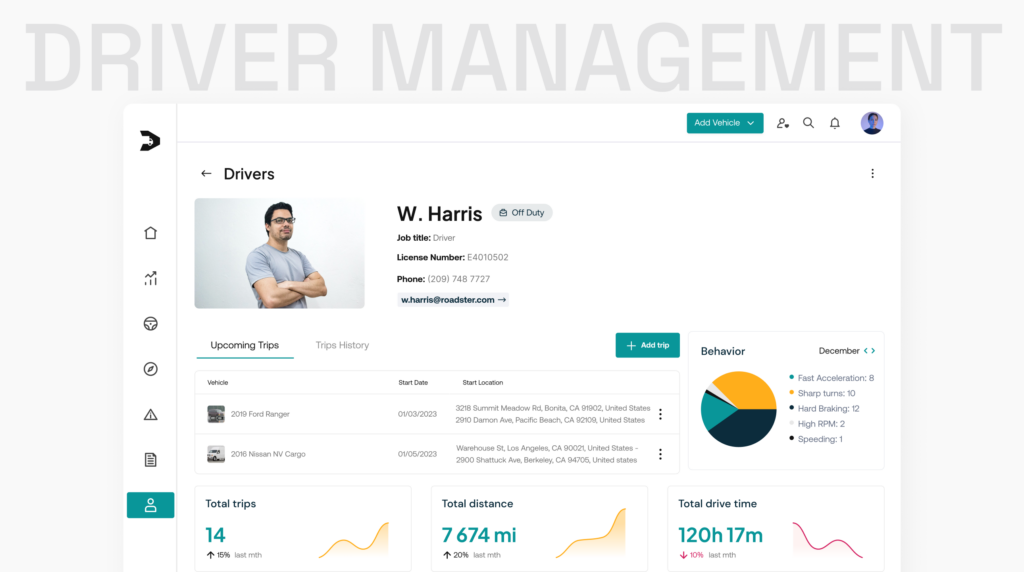

2) Driver management and safety strategies

The importance of drivers in maintaining and operating the fleet efficiently cannot be overstated. Skilled and well-trained drivers not only ensure the safety of the vehicles but also contribute significantly to reducing wear and tear, thus preventing unnecessary breakdowns. Implementing thorough training programs and adopting a culture of safety can lead to more conscientious handling of vehicles, which is essential for avoiding downtimes and ensuring the fleet’s longevity.

- Prioritize driver happiness

Ensuring your drivers are content is crucial for keeping your fleet operational. Regular and transparent communication, along with competitive compensation and benefits, are key components.

It’s important to invest in enhancing driver comfort, such as offering in-cab amenities and perks like fuel cards with benefits such as free coffee.

You can create a driver reward program to acknowledge your team’s efforts and keep them enthusiastic about their roles.

- Invest in driver training and emphasize the importance of safe driving practices

Educating drivers on proper vehicle operation and maintenance can prevent unnecessary wear and tear. Regularly provide your drivers with training on safe driving practices and vehicle care. This investment not only minimizes the risk of breakdowns but also promotes a safer driving environment.

Teaching your drivers the ins and outs of how to handle their vehicles correctly can really save you from a lot of unnecessary repairs. Providing insights into vehicle mechanics and maintenance routines equips drivers to address minor issues before they escalate into costly repairs. It’s all about giving them the know-how to keep those vehicles in top shape for as long as possible.

Educating drivers on maintaining focus while driving, staying attentive to other vehicles on the road, and avoiding aggressive maneuvers such as sudden gear shifts and sharp turns significantly reduces the likelihood of accidents and breakdowns.

- Leverage fleet driving data to monitor and improve driving behaviors

Instead of assuming proficiency behind the wheel, leverage fleet data to gain insights into your drivers’ safety practices. While your technicians might excel in their respective fields, their driving habits could be a potential source of downtime. You can utilize fleet tracking technology to gather concrete evidence of unsafe driving instances, offering a visual representation of when and where these incidents occur.

Conducting data-driven conversations with your drivers is essential. Present them with specific examples from the collected data, highlighting instances of unsafe driving. By addressing these concerns proactively, you can mitigate potential risks and ensure smoother operations for your fleet.

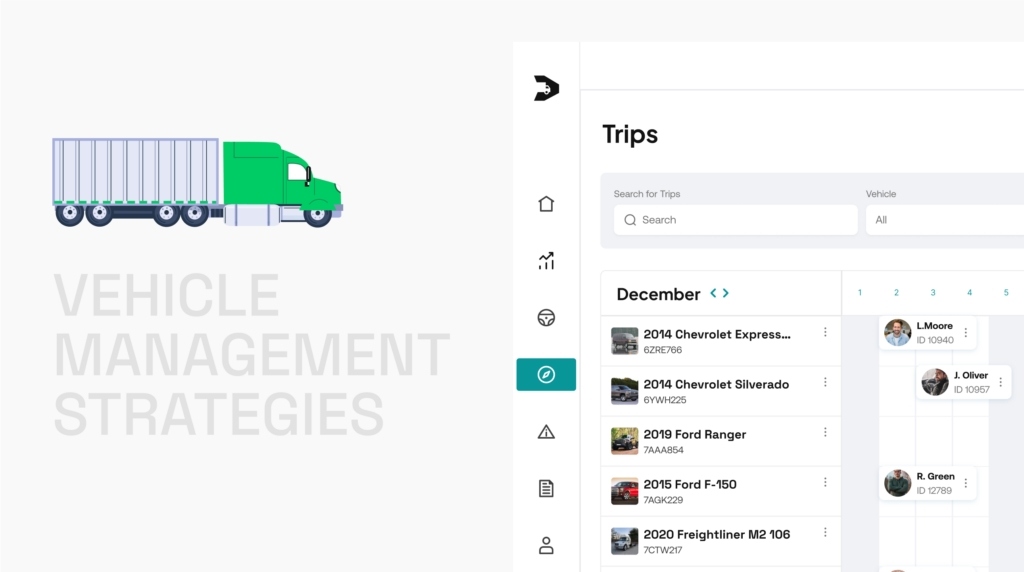

3) Vehicle management strategies

Effective vehicle management strategies are crucial for minimizing fleet downtime and maximizing operational efficiency. These proactive measures ensure that vehicles are in optimal condition, reducing the likelihood of downtime and extending the lifespan of the fleet. Such strategies not only save on repair costs but also improve the reliability and availability of vehicles for operations.

- Choose low-maintenance vehicles for your fleet

Choosing the right vehicles minimizes downtime by ensuring they meet operational demands and are less prone to breakdowns.

Picking vehicles known for needing fewer fixes can keep your fleet moving smoothly. It’s a smart move to go for brands with a solid reputation for reliability and lower maintenance costs.

- Invest in newer models

Investing in newer models with advanced technology can lead to fewer mechanical issues and lower maintenance costs over time. Though initially costly, it pays off in the long run.

Believe it or not, getting new vehicles can cut down on your headaches and save you some cash in the long run. Sure, it sounds like a big spend upfront, but here’s the deal: the latest models come packed with tech that just works better and breaks down less. Plus, they usually come with warranties that last a few years, meaning any hiccups they do have won’t cost you extra to fix.

This approach isn’t just about spending money; it’s about smart investing. Newer vehicles mean less downtime, fewer repairs, and, thanks to those warranties, potentially zero repair costs for a good chunk of time.

- Develop a vehicle replacement strategy and prioritize lifecycle planning

As vehicles age, their performance tends to decline, leading to more frequent unplanned downtime. By regularly assessing the condition of your fleet and establishing clear criteria for replacement, you can anticipate and address potential issues before they lead to significant downtime.

Implementing a structured replacement schedule based on factors such as mileage, maintenance history, and anticipated repair costs can help optimize fleet performance and minimize disruptions.

Despite diligent maintenance, every vehicle has a finite lifespan. Develop a detailed life cycle plan for each vehicle to anticipate replacements or refurbishments. With a well-defined lifecycle plan in place, you can ensure uninterrupted operations.

4) Operational efficiency strategies

By strategically enhancing operational efficiency, companies can significantly mitigate these issues and streamline their vehicle management processes.

- Optimize route planning

Efficient route planning stands as a cornerstone in mitigating fleet downtime. Elements such as road conditions, speed limits, weather conditions, traffic patterns, and driver fatigue significantly impact vehicle uptime.

To enhance this process, utilize historical data to identify the most efficient routes for drivers. Incorporating this data into scheduling and route optimization ensures vehicles operate at peak performance.

- Streamline inventory management

This involves meticulous planning, tracking, and optimization of spare parts inventory. One actionable approach is to implement advanced software tools specifically designed for monitoring and maintaining stock levels. These tools provide real-time insights into inventory status, enabling proactive decision-making and ensuring that essential spare parts are always available when needed.

Leveraging advanced tracking technologies enables real-time visibility into inventory movements, facilitating proactive replenishment and reducing the likelihood of stockouts.

- Build strong supplier relationships

Forge connections that go beyond mere transactions. These relationships grant you immediate access to crucial information and expedited support in times of crisis.

Also, cultivating these partnerships may lead to favorable pricing for essential fleet components.

- Leverage 24-hour fueling services

Every minute a vehicle spends refueling during the day is a minute it’s not on the road, completing routes and serving customers. By shifting fueling tasks to off-hours, like when drivers are catching some Z’s, you’re effectively reclaiming valuable time that would otherwise be lost. This simple adjustment can translate into significant reductions in downtime over the span of a year.

By embracing 24-hour fueling services, you’re not just avoiding daytime interruptions; you’re optimizing your fleet’s operational rhythm by synchronizing fueling with natural downtimes. Plus, it empowers your drivers to focus solely on their routes during peak hours, without the hassle of detouring for refueling stops.

- Make the most of planned downtime

Fleet downtime can become an asset when strategically planned in advance. Utilize periods when vehicles are naturally inactive, such as during driver vacations or temporary breaks, to conduct thorough vehicle inspections and necessary maintenance tasks.

You can identify specific days within the month when certain vehicles won’t be utilized for deliveries, allocating these intervals for comprehensive inspections and essential maintenance procedures.

5) Financial and contractual strategies

Let’s delve into strategic financial management strategies that can minimize fleet downtime and enhance operational efficiency.

- Hire contract vehicles during peak seasons to flexibly adjust fleet size

During peak seasons or busier times of the year, consider hiring contract vehicles to supplement your fleet. By tailoring your fleet size to match demand fluctuations, you can avoid maintaining excess vehicles during periods of low activity.

But explore contract options carefully to ensure they align with your industry needs and offer favorable terms. Negotiate terms that prioritize flexibility and cost-effectiveness, allowing you to scale your fleet up or down as needed without incurring unnecessary maintenance expenses.

- Utilize courtesy vehicles to maintain operations during repairs

Even with regular maintenance, vehicles may require downtime for repairs. One effective strategy is to request courtesy vehicles from your service providers. These vehicles can serve as temporary replacements, ensuring your fleet stays operational while maintenance is underway.

By having access to alternative vehicles, you can maintain service levels and meet customer demands without disruptions. Additionally, this strategy allows you to optimize resources and minimize revenue loss during maintenance periods.

- Opt for a full-service lease or a third-party maintenance contract.

Choosing a full-service lease or a third-party maintenance contract can significantly reduce vehicle downtime. With a full-service lease, the leasing company takes on the responsibility of maintaining the trucks, providing you with scheduled maintenance updates. This level of support adds predictability to your schedule, allowing for better planning around downtime.

Additionally, it ensures that no maintenance task is overlooked, minimizing the chances of unexpected repairs while on the road. Moreover, full-service leases often include 24/7 roadside assistance and spare units, facilitating swift resolutions and keeping your drivers on the move during unplanned repairs. If owning the trucks is preferred over leasing, opting for a third-party maintenance contract offers similar benefits and proves to be a worthwhile investment.

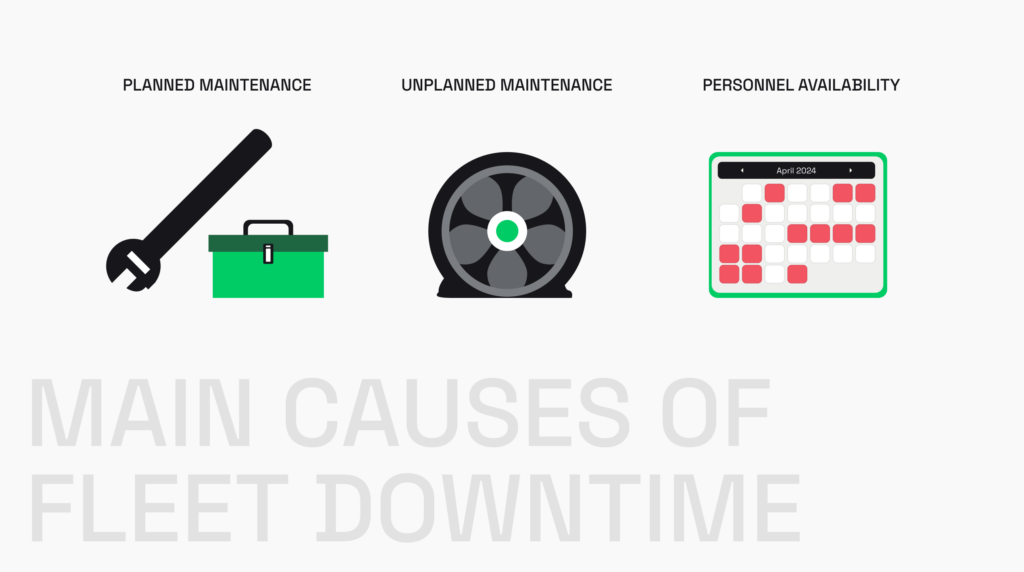

Main causes of fleet downtime

It’s inevitable that all your vehicles will require some time in the garage due to the natural wear and tear. The causes of downtime typically fall into three categories:

1) Planned maintenance

Your trucks, like any complex machinery, require regular maintenance schedules. This encompasses tasks ranging from pre-trip inspections to brake pad replacements and installing new auxiliary power units. The advantage of planned maintenance is its predictability; you know when it needs to occur and roughly how long it will take. Consequently, you can incorporate this downtime into your budget upfront. Despite being inevitable, planned maintenance is an example of downtime that can be anticipated.

2) Unplanned maintenance

Instances such as a blown tire or gasket failure are inevitable occurrences. Unplanned maintenance poses both inconvenience and expense. Paradoxically, adhering to the planned maintenance schedule is the most effective strategy for reducing such delays, ensuring smoother operation of mechanical systems. While repairs are undoubtedly essential, maintaining your trucks in optimal condition diminishes the probability of unplanned maintenance, thus categorizing it as unnecessary downtime.

3) Personnel availability

Drivers go on vacations, are subject to strict hours-of-service regulations limiting their driving to a maximum of 11 hours per shift, may fall ill, require training, or unexpectedly leave their positions. When a driver is unavailable, the truck remains inactive. Although this downtime is necessary, meticulous planning can mitigate its impact on costs.

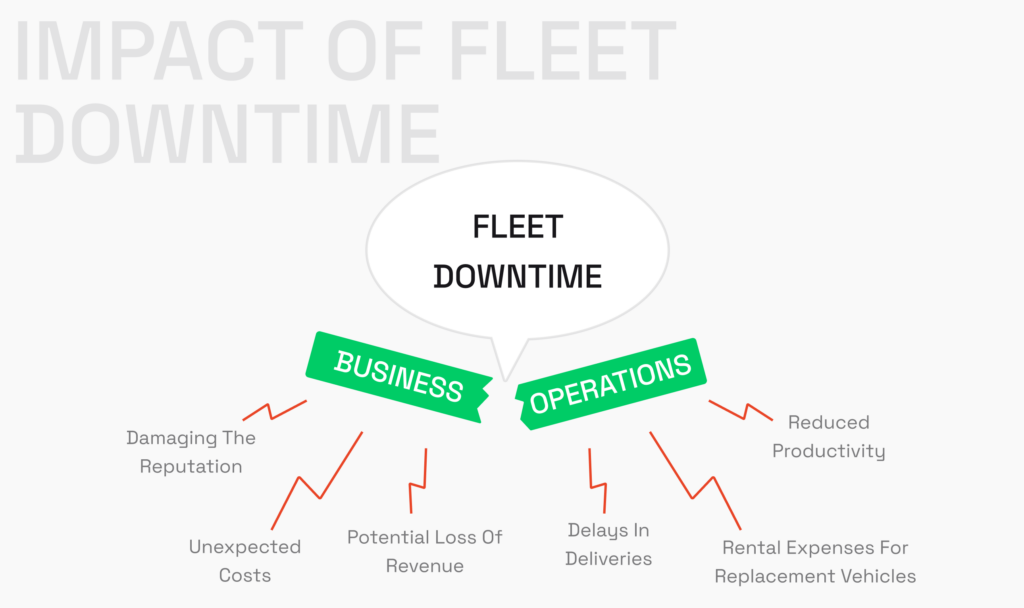

Understanding the impact of fleet downtime

Fleet downtime directly affects the ability of fleet managers to meet their operational goals and serve their customers effectively.

Firstly, downtime disrupts the regular flow of business operations. When vehicles are out of service, they cannot fulfill their intended roles, leading to delays in deliveries, reduced productivity, and potential loss of revenue. This interruption in service not only affects the bottom line but also risks damaging the reputation of the fleet company in the eyes of its customers.

Moreover, downtime often results in unexpected costs. Beyond the expenses associated with repairs or maintenance, there are indirect costs such as idle labor, rental expenses for replacement vehicles, and the cost of expedited shipping to fulfill customer orders. These costs can quickly accumulate, putting additional strain on the fleet’s budget.

Furthermore, prolonged downtime can have cascading effects on the entire operation. It may lead to scheduling conflicts, missed deadlines, and increased pressure on the remaining vehicles in the fleet to pick up the slack. This can exacerbate wear and tear on those vehicles, leading to a cycle of increased maintenance needs and further downtime.

How much can downtime cost your fleet?

How much downtime could set your fleet back? Let’s break it down so youo you can see just what’s at stake.

1) Maintenance and parts costs

Neglecting regular maintenance means more trips to the parts store, and that’s money out of your pocket. Those unexpected breakdowns? They’re dipping into your profits, plain and simple.

2) Labor costs

Think about it—every hour your technicians spend fixing a downed vehicle is money flying out of your pocket. Overtime? Yeah, that’s a costly side effect of not keeping up with maintenance schedules.

3) Replacement costs

Inadequate maintenance practices or a lack of visibility into maintenance schedules can escalate the risk of major repairs or replacements, such as transmission issues. Implementing a robust fleet maintenance program can mitigate the need for expensive parts, repairs, and labor.

4) Opportunity losses

Extended vehicle downtime can disrupt your operational workflow, causing delays in fulfilling customer requests.

Totaling these expenses offers a comprehensive view of the financial toll of downtime on your organization. However, manual calculation methods are prone to errors and time-consuming. Utilizing dedicated fleet maintenance software can streamline expense management processes, providing accurate insights into the potential costs of fleet downtime.

How fleet management software helps avoid downtime

The key to minimizing downtime lies in consistent monitoring of your vehicles, drivers, and maintenance schedules. While robust maintenance programs and training schedules are essential, leveraging technology alongside human resources can significantly enhance vehicle uptime. Fleet management software stands out as a powerful tool in managing fleet downtime.

Fleet management software operates by collecting comprehensive data on each vehicle and driver, and transmitting it to a centralized database. This aggregated data empowers fleet managers to prevent downtime through the following mechanisms:

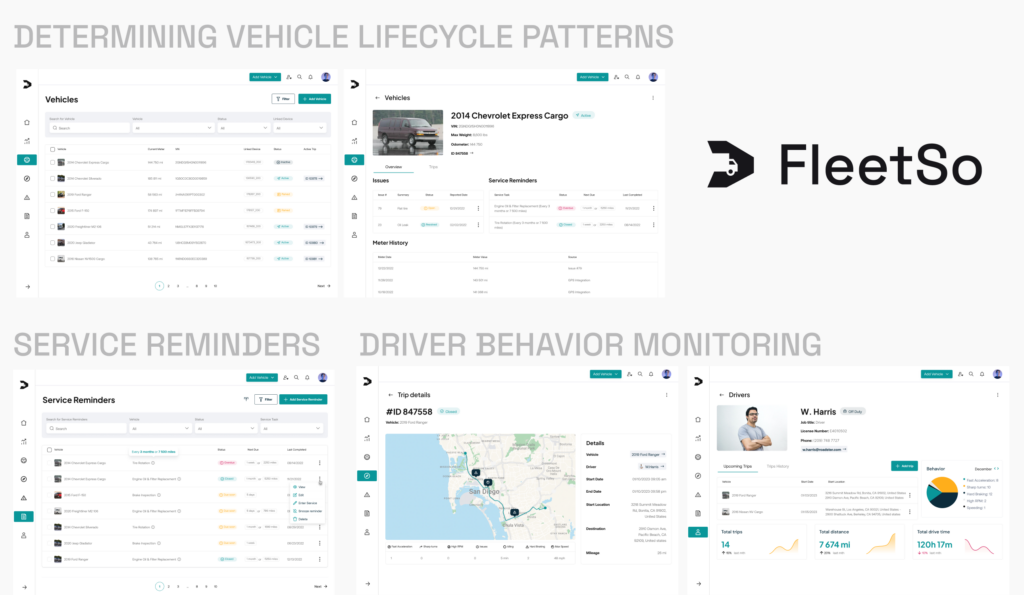

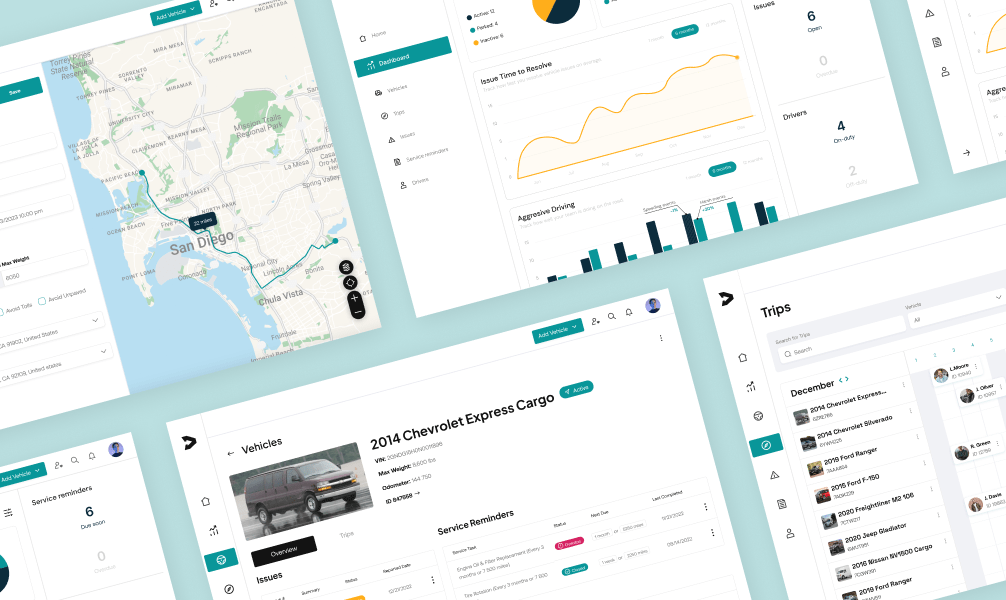

Driver behavior monitoring

By utilizing GPS and accelerometer data, fleet management software tracks driver speeds and detects harsh driving patterns. This information enables managers to pinpoint problematic driving behaviors and implement targeted retraining initiatives for the drivers in need.

Analysis of downtime data

The software systematically tracks downtime occurrences, identifying recurring patterns and failures. It highlights whether specific causes or drivers are consistently associated with downtime, facilitating proactive intervention to mitigate future disruptions.

Service reminders

Fleet management software allows setting reminders based on predefined intervals such as mileage or usage hours. These reminders ensure timely servicing, preventing oversight of critical maintenance tasks and maintaining vehicles in optimal condition.

Tracking repair data

Detailed service histories for each vehicle are maintained within the software, enabling the identification of upcoming maintenance requirements. By tracking repair data, managers can anticipate service needs and schedule maintenance proactively, reducing unplanned downtime.

Determining vehicle lifecycle patterns

Utilizing fleet data analytics, managers can discern vehicle lifecycle patterns and service history trends. This information aids in establishing appropriate timelines for vehicle replacement, ensuring fleet renewal occurs at optimal intervals.

Through these functionalities and more, fleet managers gain comprehensive control and insights into their vehicle fleet and operational processes. For a thorough understanding of the process of building tailor-made software system for your company, consider checking out this comprehensive guide on fleet management software engineering.

Best fleet management software tools for reducing fleet downtime

The software solutions below are designed to effectively manage your fleet and reduce downtime. They streamline complex processes, optimize maintenance schedules, and ensure that your vehicles spend more time on the road and less in the shop

1) Rand McNally

For over a century, Rand McNally has been a trailblazer in mapping and navigation. Today, they lead the way in software for connected cars, fleet management, and cutting-edge hardware.

2) Fleetio

Fleetio is a cloud-based software that equips businesses with tools for vehicle management, maintenance scheduling, and fuel consumption tracking. With features like real-time fleet tracking and automated maintenance schedules, Fleetio helps streamline operations to minimize downtime and enhance fleet efficiency.

3) Onfleet

Specializing in delivery management, Onfleet optimizes last-mile delivery operations with real-time tracking, driver dispatching, and customer notifications. By improving delivery efficiency, Onfleet helps reduce downtime and ensures timely deliveries.

4) Samsara

Samsara encourages safe and efficient driving practices among your team, ultimately reducing the risk of accidents and breakdowns that can lead to downtime. Packed with features to streamline operations, Samsara can help to keep your fleet running smoothly.

How we build customized software to help companies reduce fleet downtime

Regularly ranked among the Top Custom Software Development Companies on Clutch, Volpis has been leveraging the power of technology to assist business owners in reducing fleet downtime and achieving unparalleled efficiency. We invite you to explore our portfolio for a detailed look at the innovative software systems we have developed for our valuable clients.

For example, FleetSo is a web application that includes features such as real-time GPS tracking, automated dispatch, driver performance monitoring, and maintenance scheduling, among others.

If you’re planning to develop custom software solutions for your business, you may find this guide for building fleet management software useful. Check out our comprehensive resource to learn about trends, best practices, costs involved and so much more.

And if you have any questions or need further information about strategies for reducing fleet downtime or creating a custom fleet management software system, please do not hesitate to contact us at info@volpis.com

FAQs

Downtime in fleet management refers to the period when vehicles are out of operation due to maintenance, repairs, or unforeseen issues, resulting in decreased productivity and increased costs for the fleet owner.

To reduce vehicle downtime, implement regular vehicle monitoring, maintenance programs, and leverage technology like fleet management software to identify and address issues promptly.

Improving fleet maintenance involves implementing scheduled maintenance plans, tracking service histories, and using data analytics to optimize maintenance schedules and minimize downtime.

Implement proactive maintenance schedules, leverage fleet management software for real-time monitoring, and provide comprehensive driver training to minimize accidents and breakdowns.

Fleet management costs can be reduced by optimizing routes to minimize fuel consumption, implementing efficient maintenance programs to prevent costly breakdowns, and utilizing telematics technology to track vehicle usage and driver behavior for better resource allocation.

Predictive maintenance software can enhance the longevity of a truck fleet by analyzing data to predict potential failures, allowing for timely repairs before issues escalate, thus reducing downtime and extending the lifespan of vehicles through proactive maintenance interventions.

Kostya Khuta, the CEO of Volpis, is an expert in crafting custom software solutions for the Fleet Management, Logistics, and Transportation industry. With over 8 years of experience, he leads the way in delivering innovative and tailored solutions to meet industry-specific needs.