Do you need to reduce fleet costs?

Over the past 8 years, our fleet management software developers have perfected their craft by creating custom software solutions tailored to the specific needs of various fleets, and we want to share some of the top strategies we’ve discovered for slashing costs effectively.

In this article, we’ll explore not just the individual expenses but also how they integrate into the overall financial management of a fleet. We’ll provide insight into the key financial metrics crucial for fleet management, and how to effectively manage fleet expenses by analyzing these critical indicators.

And if you have any questions about fleet cost reduction approaches, you can always reach out to us via info@volpis.com with any questions. We would be happy to answer all your questions and create a customized system for managing your fleet (or add new features) that would give you a bird’s-eye view, allowing for timely decisions that minimize waste.

Understanding fleet costs involved: Total Cost of Ownership (TCO) and Cost Per Mile (CPM)

Understanding the Total Cost of Ownership (TCO) and cost per mile (CPM) is foundational for managing fleet costs effectively. These metrics provide a comprehensive view of the expenses involved in operating a fleet, which is crucial for making informed decisions to enhance profitability.

1. What is the Total Cost of Ownership (TCO) and how to calculate it

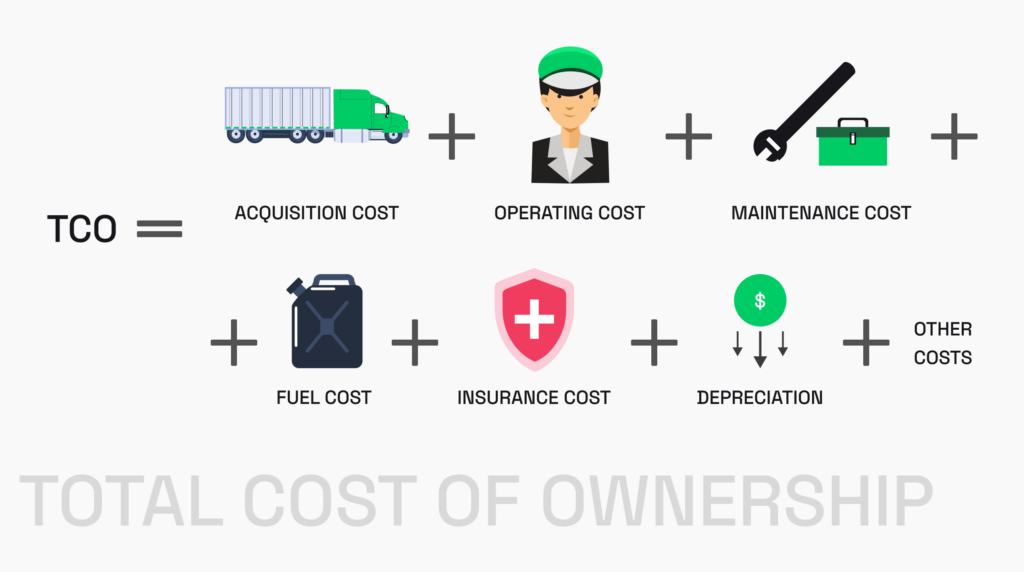

Total Cost of Ownership (TCO) encompasses all costs associated with acquiring, operating, maintaining, and ultimately disposing of a fleet vehicle. By calculating TCO, you can identify which fleet vehicles are financial drains versus those contributing to your bottom line.

To accurately calculate the TCO for your fleet, you need to consider all costs from acquisition through to disposal:

TCO = Acquisition cost + Operating costs + Maintenance costs + Fuel costs + Insurance costs + Depreciation + Other costs

By breaking down the TCO into these constituent parts, fleet managers can gain a thorough understanding of where their money is going and identify specific areas where cost reductions can be made:

- Acquisition cost: The initial cost of purchasing or leasing the vehicle, including taxes, fees, and any additional expenses associated with acquiring the asset.

- Operating costs: Costs associated with operating the vehicle, such as driver wages, tolls, permits, and other expenses directly related to the day-to-day operation of the vehicle.

- Maintenance costs: Expenses incurred for routine maintenance, inspections, repairs, and replacement parts to keep the vehicle in good working condition.

- Fuel costs: Expenses related to purchasing fuel to power the vehicle over its lifespan, including the cost of fuel and any associated taxes or surcharges.

- Insurance costs: Premiums paid to insure the vehicle against accidents, liability claims, theft, and other risks.

- Depreciation: The decrease in the value of the vehicle over time due to wear and tear, age, and mileage. Depreciation is often calculated based on the vehicle’s purchase price and expected lifespan.

- Other costs: Any additional expenses not covered by the above categories, such as financing costs, taxes, registration fees, fines, or penalties.

Understanding TCO helps identify the true cost of owning and operating each vehicle in the fleet. This insight is critical for making strategic decisions such as vehicle acquisition, setting budgets, and identifying areas where cost-saving measures can be most effectively applied.

2. What is Cost Per Mile (CPM) and how to calculate it

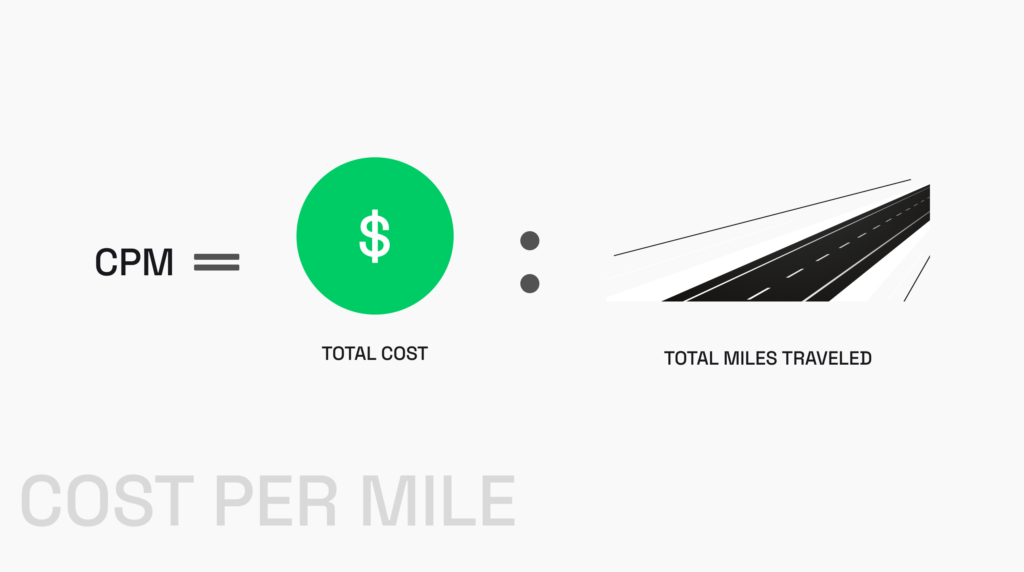

Cost per mile (CPM) measures the average cost incurred for each mile driven by a fleet vehicle. It is calculated by dividing the total operating costs by the total miles traveled. This gives you the average cost incurred for each mile driven by the vehicle:

CPM = Total Cost/Total Miles Traveled

Total Cost = The total cost associated with operating the vehicle over a specific period, which may include fuel, maintenance, repairs, insurance, depreciation, and other expenses.

Total Miles Traveled = The total number of miles traveled by the vehicle during the same period.

It’s essential to track and analyze the CPM regularly to monitor the efficiency of your fleet operations and identify areas where costs can be reduced or optimized. CPM provides a clear metric to gauge the financial impact of driving a vehicle and helps identify opportunities to reduce costs on a per-mile basis. Regular tracking and analysis of CPM allow fleet managers to compare the cost-effectiveness of different vehicles within the fleet and make informed decisions.

Best ways to reduce fleet costs (how to reduce Cost Per Mile)

Reducing fleet costs is all about making informed decisions that add up to significant savings over time. Let’s dive into some of the best strategies that can help fleet managers achieve just that. Keep in mind that robust fleet management software helps implement and manage all these strategies efficiently.

1) Acquisition costs

Diving into the numbers related to procurement activities, including acquiring vehicles and parts, it’s where you can find those big opportunities to save.

- Optimize purchasing processes

Reducing initial fleet costs doesn’t mean sacrificing quality. Utilizing cooperative purchasing agreements lets you secure better deals with less administrative hassle.

Establishing multi-year contracts with suppliers can lock in prices, protecting you from market fluctuations. Vendors are often willing to negotiate prices to secure long-term business, offering an opportunity for savings.

- Centralize fleet procurement

Centralizing your fleet’s procurement process allows for bulk purchasing discounts, streamlined ordering processes, and stronger negotiating power with suppliers. This consolidation leads to cost efficiencies across the board, from vehicle acquisition to maintenance and parts.

The power of centralized procurement is evident in the experiences of large fleet operators, such as the United States Postal Service, which has leveraged its massive buying power to negotiate favorable terms with suppliers, achieving millions in savings. By treating procurement as a strategic function, fleets can extract maximum value from every dollar spent.

- Consider vehicle leasing

Without the hefty upfront costs of purchasing, fleet leasing offers a cost-effective alternative to ownership. Also, it often includes maintenance packages, reducing unexpected repair bills. This strategy works particularly well for fleets needing to upscale or downscale quickly in response to market demands.

The benefits of leasing extend to newer, more fuel-efficient fleet vehicles that might otherwise be out of reach financially. Electric and hybrid lease vehicles could offer better lifetime savings compared to their owned counterparts, factoring in lower fleet fuel and maintenance costs over the lease term.

- Keep up with warranties to avoid paying for repairs that are covered

Staying on top of warranty coverage for vehicles and parts ensures you’re not paying out of pocket for parts or services that are already covered. Implementing a system to track warranties can save thousands per year in avoided repair costs.

The key to harnessing warranties lies in meticulous record-keeping and regular reviews of warranty statuses. This proactive approach ensures that fleet managers can claim warranty repairs before coverage expires, maximizing the financial benefits of warranties.

2) Operating costs

Boosting your fleet’s operational efficiency is all about the details. It’s finding those little tweaks in your daily operations that can lead to big savings over time.

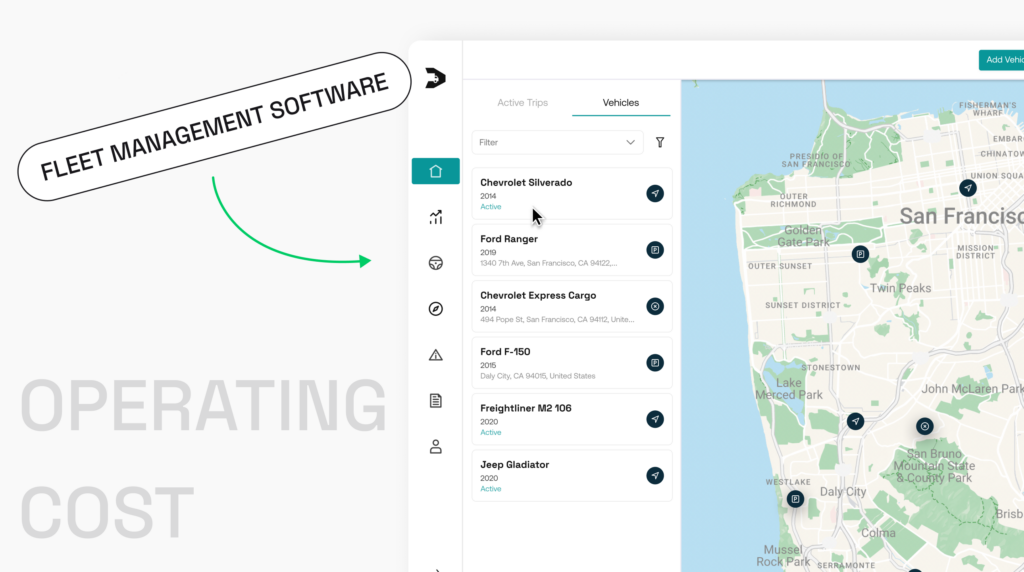

- Implement fleet management software

Adopting a fleet management platform solution helps to reduce costs by integrating data across different aspects of fleet management (from vehicle tracking to maintenance scheduling) and providing a panoramic view of fleet operations.

This helps fleet managers identify inefficiencies and spotlight areas for cost reduction. For instance, real-time tracking features enable swift decision-making, reducing vehicle idle times and optimizing route planning.

There are many fleet management software options on the market to choose from. But often, these off-the-shelf solutions lack specific features that could benefit your company, or they may include unnecessary functionalities. In such instances, opting for a custom-built software solution tailored to your business’s precise needs might be the ideal route.

Tapping into technology is a game-changer. It’s about getting all the data you need on your screen to make those cost-cutting decisions feel less like guesswork and more like a well-informed strategy.

- Implement telematics systems

Telematics systems are a goldmine of data, offering insights into vehicle performance, driver behavior, and operational efficiency. This real-time information enables fleet managers to make informed decisions that can lead to substantial cost savings.

For example, telematics can pinpoint inefficient routes, excessive idling, or aggressive driving habits that increase fuel usage. Adjustments based on telematics data have helped companies like Verizon reduce fuel costs significantly by identifying and addressing these inefficiencies.

Moreover, the adoption of telematics technology supports preventive maintenance strategies by monitoring vehicle health in real-time, allowing for issues to be addressed before they escalate into costly repairs.

- Monitor driver behavior

Speeding, aggressive acceleration, and unnecessary idling all lead to increased fuel consumption and maintenance needs. Implementing a monitoring system through telematics can help identify and correct inefficient driving habits. Providing drivers with feedback and training based on their behavior can lead to more fuel-efficient driving practices.

Companies have seen significant savings by implementing driver scorecards and incentive programs that promote safe and efficient driving. These programs not only reduce fuel and maintenance costs but also contribute to the overall safety and longevity of the fleet.

- Implement a driver reward program

You can create a driver reward program with the goal of fuel efficiency improvements. The key is to ensure that the program is seen as a genuine effort to recognize and appreciate the hard work and dedication of your drivers.

Implementing driver scorecards to monitor and reward efficient driving can promote a culture of cost-consciousness and safety, leading to a more profitable fleet operation.

3) Maintenance costs

Consistent fleet maintenance will help to keep your fleet in top shape, so you’re spending less on repairs.

- Schedule regular maintenance

By scheduling regular check-ups, fleets can anticipate and spread out maintenance costs, avoiding the financial strain of unexpected repairs.

Implementing a strict preventative maintenance schedule extends the life of your vehicles, ensuring they run optimally and consume fuel more efficiently. Well-maintained vehicles are less likely to break down, saving on costly emergency repairs and minimizing downtime.

And transitioning to a predictive maintenance approach can also lead to better fleet budget predictability. Predictive fleet maintenance is a proactive approach to fleet management that uses data analytics and predictive modeling to anticipate when a vehicle may require servicing. This method employs advanced technologies like Internet of Things (IoT) sensors, artificial intelligence, and machine learning to analyze a wide range of vehicle parameters, identifying possible issues before they escalate into significant problems.

4) Fuel costs

Optimizing fuel use is not just about filling up less; it’s about making moves that benefit both your bottom line and the environment.

- Adopt efficient fuel management practices

Investing in fuel-efficient vehicles and training drivers in eco-friendly driving techniques can lead to significant savings.

Walmart’s fleet, for example, has achieved remarkable fuel efficiency, saving $140 million and avoiding 87,000 metric tons of CO2 by really digging into the data and understanding trends where they can improve.

Regularly analyzing fuel consumption data allows for the identification of trends and outliers, guiding targeted interventions that can reduce fuel expenses. Practices such as reducing vehicle weight, maintaining optimal tire pressure, and minimizing idling are straightforward yet effective tactics that help to optimize fuel consumption and contribute to a leaner fuel budget.

- Leverage fuel cards and monitor consumption

Fuel cards offer the dual benefit of convenience and control over fuel expenditures. They simplify the process of fueling up and provide detailed reports on fuel consumption and spending. Additionally, many fuel card programs offer discounts, further reducing fleet fuel costs.

Regular analysis of fuel card data can uncover inefficiencies and opportunities for cost savings, such as identifying underperforming vehicles that consume more fuel than expected or pinpointing fueling stations with the best prices.

By actively managing fuel purchases and leveraging the data provided by fuel cards, fleets can achieve more predictable fuel spending and improve their bottom line.

- Explore alternative fuels

With fuel prices in constant flux, alternative fuels present an opportunity for substantial savings. Transitioning to electric, hybrid, or natural gas-powered vehicles can seem costly at first, but the long-term savings are undeniable.

For example, an EV requires only about half the energy needed for a gasoline-powered internal combustion engine. Electricity prices are much more stable, helping to keep your fuel costs predictable and easier to fit into your budget. Beyond fuel, the maintenance costs of EVs can also be lower than those of conventional vehicles.

Electric vehicles could save tens of thousands of dollars over the life of vehicles, according to a report from Clean Energy Canada. The report compares the total ownership costs of electric vehicles with their gas-powered equivalents (from purchasing to refueling and maintenance) and in every case, electric vehicles come out cheaper than the gas alternative.

- Reduce mileage through efficient route planning

Technology can now predict traffic patterns, weather conditions, and delivery windows, enabling fleets to minimize wasted miles and fuel. Dynamic routing, as practiced by companies like FedEx, adapts to real-time conditions, ensuring drivers take the most efficient paths to their destinations.

Incorporating GPS and routing software into your fleet operations can transform how you approach deliveries and service calls. By continually seeking the shortest, quickest routes, you not only save on operational costs but also enhance the service level provided to customers.

Efficient route planning also involves strategic planning of multi-stop trips, ensuring that vehicles are loaded in a way that minimizes backtracking and empty runs. This approach not only helps to reduce fleet fuel costs but also maximizes vehicle utilization, enhancing the overall efficiency of your entire fleet.

- Train drivers in fuel-efficient driving techniques and proper vehicle care

Beyond just operating the vehicle, drivers trained in fuel-efficient driving techniques, safety practices, and proper vehicle care can significantly lower operating costs.

Obeying the speed limit, accelerating and braking gently and gradually, and reading the road ahead can improve the fuel economy of your vehicle by 15%–30% at highway speeds and 10%–40% in stop-and-go traffic.

Incorporating regular training sessions and incentivizing efficient driving practices encourage drivers to adopt behaviors that will be instrumental in reducing fuel consumption, maintenance costs, and the likelihood of accidents.

- Monitor and reduce idle time

Excessive idling consumes fuel unnecessarily, contributes to vehicle wear and tear, and increases emissions. Implementing policies that limit idling time can therefore lead to significant savings.

For example, the City of New York implemented an anti-idling campaign that not only raised awareness among city drivers but also resulted in substantial fuel savings and reduced emissions across its fleet.

Telematics can play a key role in monitoring idle times and providing data to support the enforcement of idling policies. By identifying vehicles or drivers with high idle times, fleet managers can take targeted actions to address the issue, such as additional training or vehicle adjustments, further driving down operational costs.

- Eliminate unnecessary weight

Carrying unnecessary equipment or materials not only adds to fuel consumption but also increases wear and tear on the vehicle. Providing centralized storage space for equipment not in use encourages drivers to unload unnecessary weight, optimizing fuel consumption.

Regular audits of what’s being carried in fleet vehicles can uncover opportunities to lighten loads and save on fuel. This practice, coupled with driver education on the impact of excess weight on fuel economy, can foster a more cost-conscious culture within your organization.

5) Insurance costs

Insurance is a significant part of the total cost of owning and operating a fleet. It protects your business from financial losses due to accidents, theft, and other unforeseen events. However, insurance costs can vary widely, and there are strategies to help manage and reduce these expenses.

- Regularly shop for competitive quotes

Don’t just renew your insurance policies automatically. Market conditions and insurance offerings change, so it’s beneficial to shop around for competitive quotes at each renewal period. This encourages your current insurer to offer you the best possible rate to retain your business, and you might find more favorable terms with a different provider.

- Implement risk management and safety programs

Conducting comprehensive risk management and driver safety programs can significantly reduce insurance costs. Insurers often offer discounts for fleets with low accident rates and strong safety measures. Investing in driver education, safety technology, and accident prevention can lead to lower premiums.

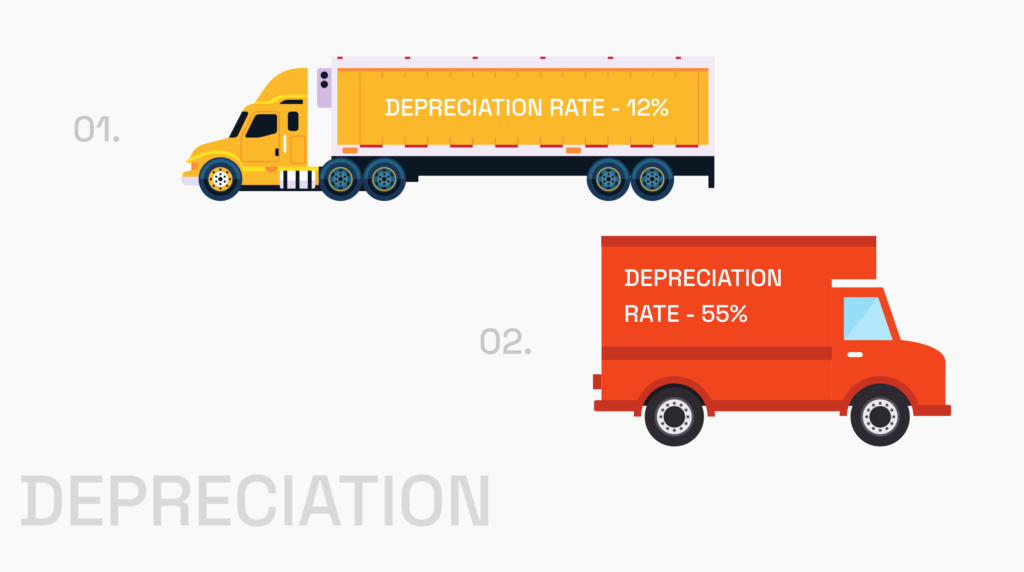

6) Depreciation

The depreciation rate describes how quickly an asset loses its value over time. In the context of fleet management, it refers to the rate at which vehicles in the fleet lose their value due to factors like wear and tear, age, technological obsolescence, and market conditions. The depreciation rate is crucial for financial reporting, tax calculations, and strategic decision-making regarding asset management.

- Balance vehicle acquisition costs and depreciation rate

The depreciation rate is the rate at which the value of an asset is reduced each year. Selecting vehicles with lower depreciation rates and considering the resale value can enhance the financial performance of your fleet. Company vehicles that depreciate rapidly may seem like a bargain initially but can result in higher total costs over their lifecycle.

Analyzing the overall cost of ownership, including depreciation, fleet fuel usage, maintenance, and resale value, allows for more informed vehicle purchasing decisions. This strategy ensures that fleets invest in fleet vehicles that offer the best long-term value, rather than just focusing on the upfront cost.

- Cycle out older vehicles

As vehicles age, they tend to require more maintenance, consume more fuel, and are prone to breakdowns, all of which can inflate costs. A thoughtfully executed replacement strategy also considers the resale value of older vehicles, turning potential liabilities into assets.

Developing a comprehensive vehicle replacement plan requires a detailed analysis of your fleet, including the lifecycle cost of each vehicle, to determine the optimal time for a replacement. This ensures that you are not spending excessively on keeping old fleets running when it would be more cost-effective to replace vehicles.

Companies like FedEx have successfully implemented vehicle replacement programs, optimizing their fleets for efficiency and sustainability while managing costs. By regularly updating their fleets, they not only benefit from advancements in vehicle technology and are able to improve fuel efficiency but also maintain a higher resale value, reducing the total cost of ownership over time.

7) Other costs

Fleets incur various other costs that can impact the bottom line. These costs might include administrative fees, fines, and compliance costs, among others. Effective management of these expenses can contribute to overall cost savings.

- Streamline administrative processes

Administration costs might not directly relate to how your vehicles operate, but they’re still important to consider. We’re talking about the costs of paperwork, admin tasks, and getting the necessary licenses for your fleet. These expenses vary based on what kinds of vehicles you have and their purposes. While not directly tied to vehicle condition, managing these costs efficiently is key to keeping overall expenses down.

Leveraging technology to automate administrative tasks can lead to substantial savings. For example, using fleet management software for tasks such as license renewals, toll payments, and compliance reporting can reduce labor hours and minimize errors that could result in fines.

- Utilize tax deductions and credits

Stay informed about tax deductions and credits available for fleet operations, such as deductions for heavy vehicles, and credits for using alternative fuels or electric vehicles.

Properly leveraging these can significantly reduce net costs. Engage a tax professional familiar with the transportation industry to ensure you’re capitalizing on all available tax benefits.

3 best fleet management software for managing fleet costs

The software tools below offer powerful ways to help manage your fleet more effectively and at a lower cost.

1) Fleetio

Fleetio is a cloud-based software that equips businesses with tools for vehicle management, maintenance scheduling, fuel consumption tracking, and more. It offers features such as real-time fleet tracking, automated maintenance schedules, and customizable reporting. This application enables businesses to streamline their operations and enhance fleet efficiency.

2) Rand McNally

For over a century, Rand McNally has been a trailblazer in mapping and navigation. Today, they lead the way in software for connected cars, fleet management, and cutting-edge hardware.

3) Onfleet

Onfleet specializes in delivery management, assisting businesses in optimizing their last-mile delivery operations. It provides functionalities like real-time tracking, driver dispatching, and customer notifications. Onfleet is designed to improve customer service and enhance delivery efficiency.

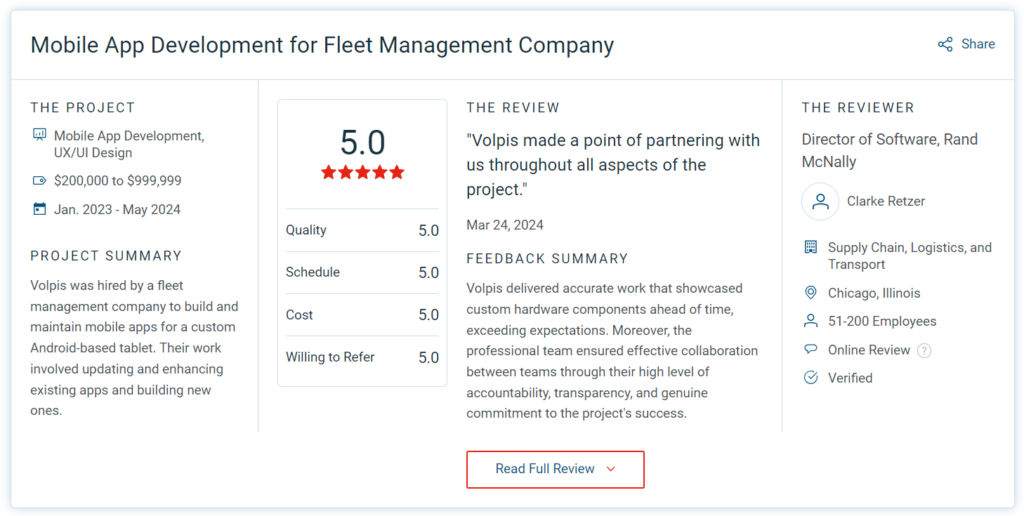

How we build custom software solutions to help fleet companies reduce costs

Regularly ranked among the Top Custom Software Development Companies on Clutch, Volpis has been leveraging the power of technology to assist business owners in achieving unparalleled cost savings. Our commitment to excellence is reflected in the glowing reviews from our customers, who consistently praise our dedication to delivering exceptional results.

Read more reviews from our valuable customers here

We invite you to explore our portfolio for a detailed look at the innovative software systems we have developed for our clients. One example is FleetSo, a web application that includes features such as real-time GPS tracking, automated dispatch, driver performance monitoring, and maintenance scheduling, among others.

We’d love to answer any questions you may have. You can reach out to us via info@volpis.com with any questions or to explore how we can be part of your journey.

FAQs

You can reduce fleet costs by implementing regular maintenance schedules to prevent costly repairs, using GPS tracking for efficient route planning, and investing in driver training programs to promote fuel-efficient driving. Leveraging telematics to monitor vehicle and driver performance also helps identify areas for cost-saving improvements.

Saving money on your fleet can be achieved by optimizing routes to reduce fuel consumption, enforcing a strict maintenance regime to avoid expensive breakdowns, and utilizing fleet management software to gain insights into operational efficiencies. Additionally, considering the overal cost of ownership when purchasing new vehicles can lead to long-term savings.

The cost of a fleet encompasses all expenses related to acquiring, operating, and maintaining a fleet of vehicles. This includes but is not limited to purchase or lease costs, fuel, maintenance and repair, insurance, and administrative expenses associated with fleet management.

To keep your fleet costs down without hurting your work, make sure your vehicles are used in the smartest way possible, keep an eye on fuel use, and teach your drivers how to be efficient. Using tech like telematics and GPS can also help you stay on top of things and keep your fleet running smoothly.

Yes, leasing vehicles can be a cost-effective option for managing your fleet because it cuts down on the initial money you need to shell out, lets you adjust your fleet size as needed, and usually covers maintenance. It’s a flexible option that can work really well if your business needs to change a lot.

Training your drivers can save you cash by encouraging them to drive safely, use less fuel, and take good care of their vehicles. When drivers know what they’re doing, you’ll spend less on repairs, fuel, and insurance.

Putting telematics to work gives you the lowdown on where your vehicles are, how they’re running, and how your drivers are driving in real time. This info lets you fine-tune your operations, spot ways to cut costs and boost your fleet’s overall performance.

When you handle buying for your fleet under one roof, you can haggle better deals, simplify your buying process, and make the most of buying in bulk. This way, you spend less on buying and maintaining vehicles and on parts, which adds up to big savings.

Kostya Khuta, the CEO of Volpis, is an expert in crafting custom software solutions for the Fleet Management, Logistics, and Transportation industry. With over 8 years of experience, he leads the way in delivering innovative and tailored solutions to meet industry-specific needs.