Managing inventory isn’t just about keeping shelves stocked – it’s about getting the right balance to meet customer demands without overloading your storage. This is where inventory management software offers a powerful solution to optimize inventory processes.

Regularly ranked among the top custom software development companies on Clutch, our team at Volpis has spent years creating custom systems for businesses. In this article, we’ll explore all the ins and outs of building a comprehensive inventory management software solution.

And if you’re thinking about building a custom inventory management software solution for your company (or adding new features), we would be happy to answer all your questions and give honest advice. You can always connect with us via info@volpis.com

What is inventory management software?

An inventory management software system is a specialized digital solution that helps businesses track, control, and optimize inventory across multiple locations, channels, and suppliers. It replaces manual stock handling with automation and real-time data — helping companies avoid stockouts, reduce excess inventory, and improve operational efficiency.

This type of inventory management solution acts as the system of record for everything related to your stock. It integrates with key platforms like POS systems, ERP, warehouse management software, and e-commerce platforms to create a single, synchronized view of inventory. From procurement to fulfillment, every movement is tracked and recorded.

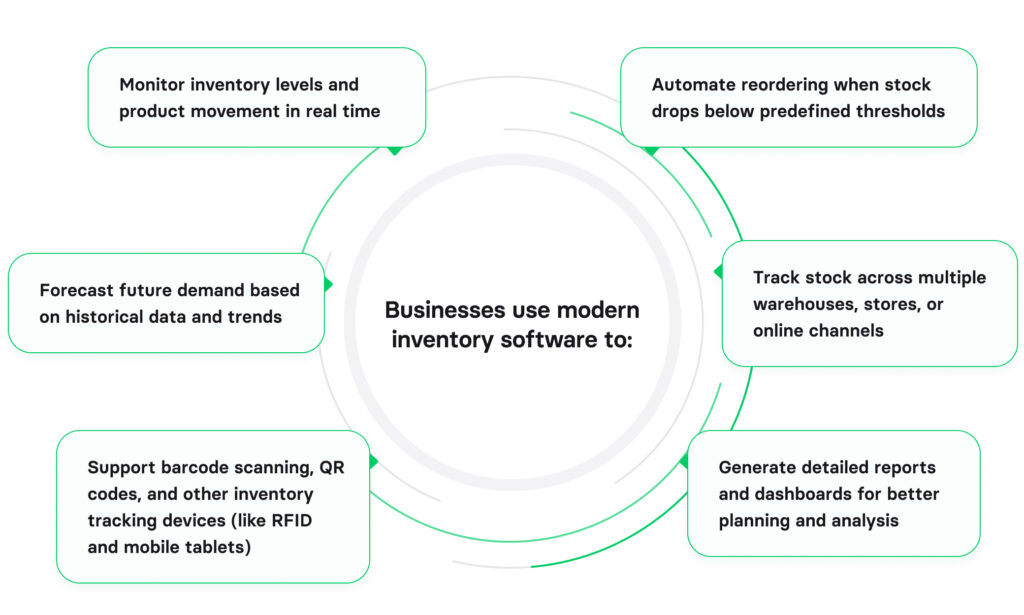

Modern inventory software enables businesses to:

- Monitor inventory levels and product movement in real time

- Automate reordering when stock drops below predefined thresholds

- Forecast future demand based on historical data and trends

- Track stock across multiple warehouses, stores, or online channels

- Support barcode scanning, QR codes, and other inventory tracking devices (like RFID and mobile tablets)

- Generate detailed reports and dashboards for better planning and analysis

Whether you’re managing spare parts, perishable goods, or retail SKUs — the right inventory system improves accuracy, speeds up operations, and empowers data-driven decisions.By implementing inventory management software, companies can achieve better inventory visibility, reduce costs associated with excess stock, and enhance overall business agility. The global inventory management software market is projected to reach USD 4.84 billion by 2032, exhibiting a CAGR of 9.7% during the forecast period (2024-2032).

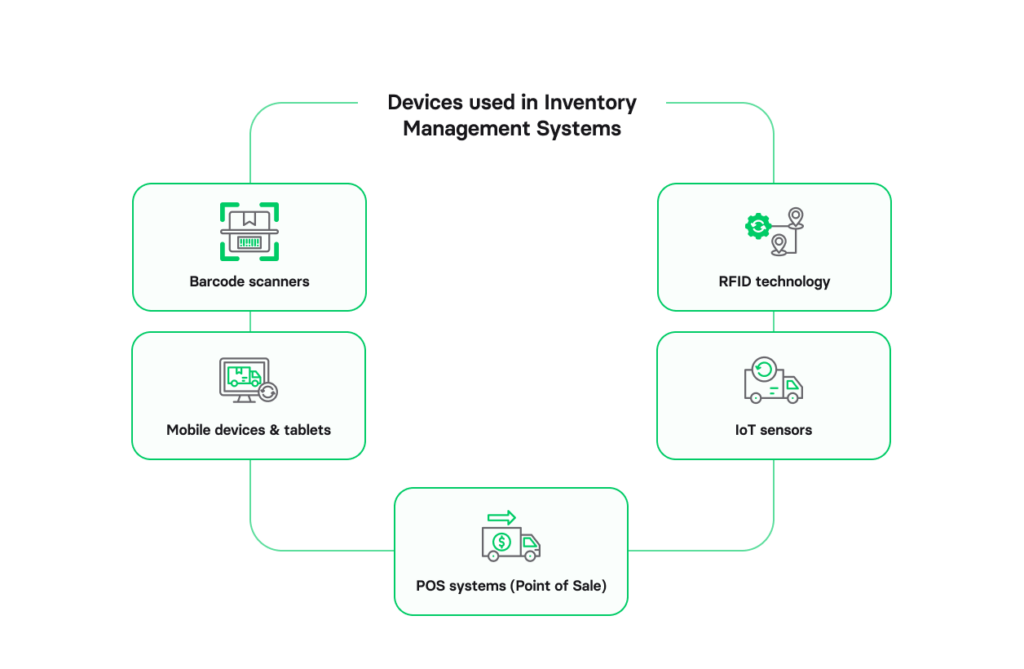

Devices used in inventory management systems

Below, we explore the common devices utilized in inventory management systems, demonstrating why incorporating these technologies is essential for businesses aiming to optimize their inventory management strategies.

Barcode scanners

Barcode scanners are a staple in inventory management systems. These devices read barcodes attached to products or equipment, translating them into electronic data that the inventory management software can process. Barcode scanners drastically reduce manual entry errors and speed up processes such as stocktaking, order processing, and inventory tracking. Their use ensures that inventory data is accurate and up to date, supporting better decision-making and operational efficiency.

RFID technology

Radio Frequency Identification (RFID) technology offers advanced tracking capabilities by using electromagnetic fields to automatically identify and track tags attached to objects. RFID tags can store significant amounts of data and provide real-time location tracking, making them ideal for large-scale operations and complex supply chains. This technology enhances visibility and control over inventory, reducing errors, theft, and loss.

Mobile devices and tablets

Mobile devices and tablets are increasingly integrated into inventory management systems to provide flexibility and mobility. These devices support applications that allow staff to perform inventory-related tasks such as checking stock levels, updating records, and processing orders from anywhere within a warehouse, or even remotely. The mobility offered by these devices enhances workforce productivity and enables real-time communication, fostering a dynamic inventory management environment.

IoT sensors

The integration of IoT (Internet of Things) sensors is an emerging trend in inventory management. These sensors collect data on inventory conditions, such as temperature and humidity, ensuring the quality and safety of sensitive products like pharmaceuticals and perishable goods. IoT sensors provide businesses with critical insights that help maintain optimal storage conditions and regulatory compliance.

POS systems (Point of Sale)

Point of Sale systems are instrumental in retail environments where immediate inventory updates are essential. These devices record each transaction and deduct the sold items from the inventory in real time, ensuring an accurate count of items in stock. POS systems align sales data with inventory records, reducing discrepancies and enhancing the accuracy of inventory reports.

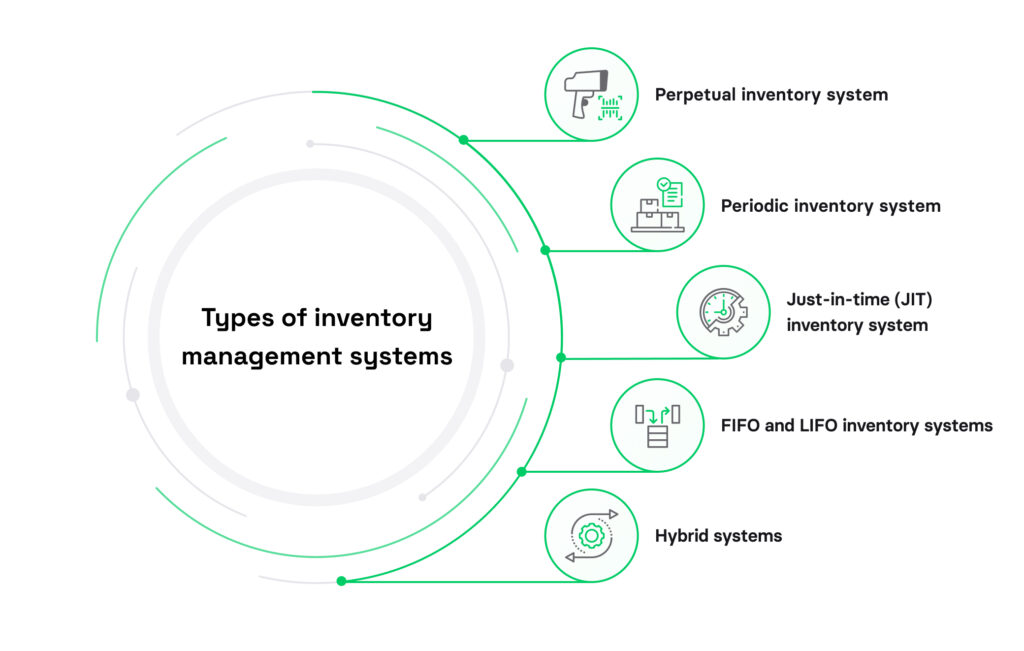

Types of inventory management systems

Choosing the right automated inventory tracking system starts with understanding the different types available — each designed to support specific operational models, product types, and business sizes. Below are the four most widely used approaches, plus a look at how modern businesses often combine them.

Perpetual inventory system

A perpetual inventory system continuously updates stock levels in real time as items are received, sold, or moved. This system uses inventory management devices like barcode scanners, RFID, or POS integrations to track inventory instantly.

- Best for: E-commerce, large retailers, and fast-moving supply chains

- Benefits: Accurate data at all times, minimal manual intervention

- Requirements: Reliable system integrations and automation

Most modern inventory software is built on a perpetual model, as it allows real-time stock visibility across multiple channels and warehouses.

Periodic inventory system

With a periodic inventory system, stock levels are updated only at scheduled intervals — typically monthly, quarterly, or annually. Inventory counts are performed manually or with scanning tools, and data is reconciled after each count.

- Best for: Small businesses with low SKU volume

- Benefits: Simple and low-cost setup

- Limitations: No real-time visibility; prone to discrepancies and delays

Example: A small brick-and-mortar shop doing quarterly inventory checks to update its spreadsheet.

Just-in-time (JIT) inventory system

A JIT inventory system aims to minimize inventory holding by receiving goods only when needed. This lean approach depends on tight coordination with suppliers and accurate forecasting.

- Best for: Manufacturers and startups looking to reduce overhead

- Benefits: Lower storage costs, reduced waste

- Risks: High sensitivity to supply chain disruptions or demand spikes

Common in industries like electronics, automotive, and food service where shelf life and space are critical.

FIFO and LIFO inventory systems

These methods focus on inventory valuation and flow rather than the timing of updates:

- FIFO (First-In, First-Out): The oldest stock is sold or used first

Ideal for perishable goods, pharmaceuticals, food & beverage.

- LIFO (Last-In, First-Out): The newest stock is sold first

Sometimes used for durable goods or where inflation skews costs. LIFO is not accepted under IFRS, but still permitted under US GAAP.

Hybrid systems

Most modern companies use a hybrid inventory management approach, combining elements of multiple systems:

- Perpetual tracking + JIT reordering

- FIFO valuation + multi-warehouse automation

- Real-time updates + periodic reconciliation

The right system depends on your business model, growth stage, and product types, and can often be custom-built to reflect your internal workflows.

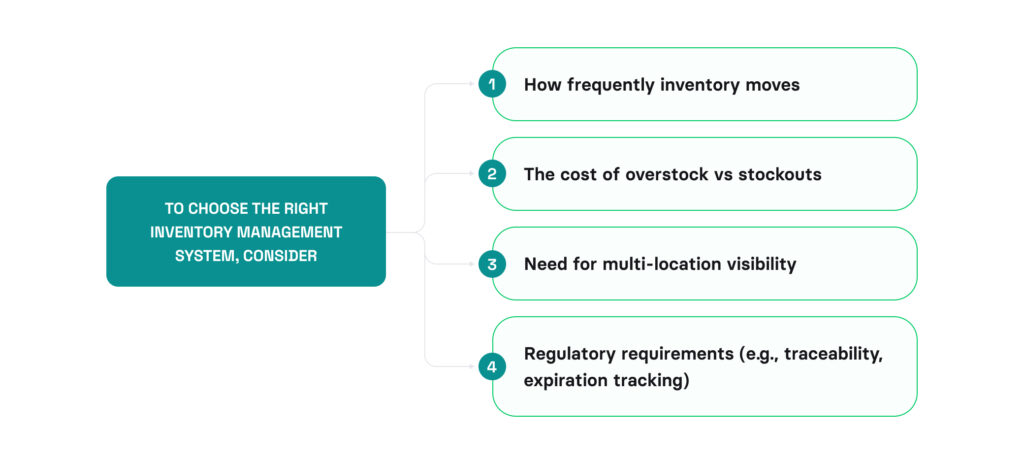

Choosing the right inventory management system

When evaluating or developing an inventory management software system, consider:

- How frequently inventory moves

- The cost of overstock vs stockouts

- Need for multi-location visibility

- Regulatory requirements (e.g., traceability, expiration tracking)

A well-chosen system isn’t just a back-office tool — it’s a foundation for profitability, scalability, and customer satisfaction.

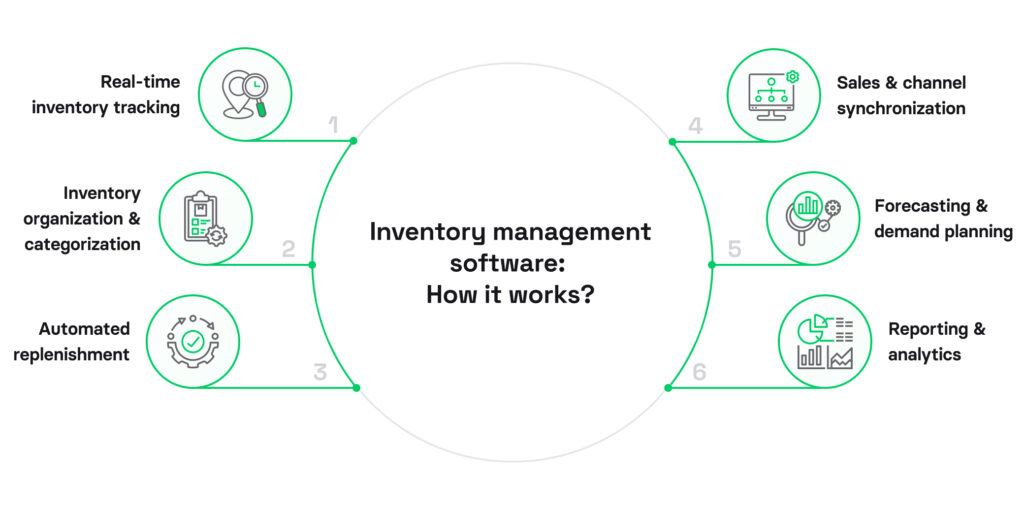

How inventory management software works

An inventory management software system acts as a real-time control center for your inventory, tracking stock movement, automating replenishment, syncing with other platforms, and generating actionable insights. It ensures you always know what you have, where it is, and what to do next.

Let’s walk through how a modern inventory management solution operates behind the scenes.

1) Real-time inventory tracking

Inventory software continuously monitors every stock change — whether it’s incoming goods, internal transfers, or outgoing shipments.

How it works:

- QR code or barcode scanning updates inventory instantly as items are received, picked, or shipped.

- RFID enables bulk scanning and location tracking without line-of-sight scanning.

- Manual adjustments can be made through web or mobile interfaces for cycle counts or corrections.

The system updates stock levels in real time across all channels and locations, helping avoid overstocking or stockouts.

2) Inventory organization & categorization

Each product is assigned a unique identifier (SKU), along with attributes like category, batch number, location, and expiration date.

The software maintains:

- Stock counts by warehouse, shelf, or bin

Groupings by product family, type, or status (available, reserved, damaged) - Batch and lot tracking, essential for industries like food or pharma

This structured data powers automation, filtering, and smart reporting.

3) Automated replenishment

The system triggers reordering based on dynamic thresholds, not guesswork.

- Reorder points are set manually or calculated using demand data

- Safety stock ensures a buffer against supply delays

- Integrated purchase orders can be sent to vendors automatically via email, API, or EDI

- Just-in-Time logic minimizes on-hand stock while maintaining availability

You reduce working capital tied in stock and never miss a reorder window.

4) Sales & channel synchronization

Inventory software integrates with POS systems, e-commerce platforms, and ERPs to ensure that sales data and stock data are always in sync.

- Stock is deducted immediately after a sale

- Backorders are created automatically if stock is unavailable

- Warehouse staff can view and prioritize fulfillment in real time

- Product availability is updated on storefronts instantly

This prevents overselling, improves customer experience, and enables smooth multi-channel operations.

5) Forecasting & demand planning

Modern systems analyze past sales, seasonal patterns, and lead times to forecast future stock needs.

- AI-based tools detect trends and auto-adjust reorder thresholds

- ABC classification helps prioritize high-impact SKUs

- Overstock and dead stock are flagged automatically

Forecasting reduces waste, improves planning, and helps avoid revenue loss from stockouts.

6) Reporting & analytics

Finally, inventory software surfaces valuable insights to support continuous improvement.

- Track stock turnover, dead stock, and inventory carrying cost

- Monitor supplier performance and delivery delays

- View dashboards with KPIs like inventory accuracy, stock velocity, and fulfillment rates

Reports can be customized and exported or integrated into business intelligence tools for deeper analysis.

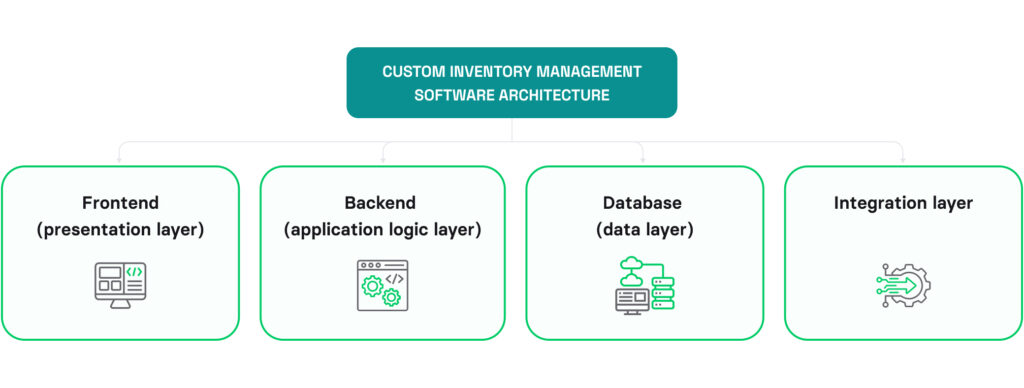

Architecture of custom inventory management software

A well-structured custom inventory management system typically follows a four-layer architecture, ensuring modularity, scalability, and integration flexibility.

1) Frontend (presentation layer)

The user-facing interface used by different roles across the organization.

- Dashboards for managers and admins

- Mobile or scanner interfaces for warehouse staff

- Real-time access to stock data, alerts, and reports

- Custom views based on role or location

2) Backend (application logic layer)

The core logic that handles all operational rules and processes.

- Manages inventory movements (receiving, shipping, transfers, adjustments)

- Triggers reorder actions based on thresholds or forecasts

- Handles batch/lot tracking, multi-location control, and returns

- Implements business logic and user permissions

- Provides APIs for frontend and external integrations

3) Database (data layer)

The centralized source of truth for all inventory-related data.

- Stores product information, SKUs, stock levels, order history, and user data

- Supports advanced queries, audits, and reporting

- Ensures consistency across all interfaces and integrations

4) Integration layer

Connects the inventory system with the rest of the business ecosystem.

- POS systems (e.g., to sync sales and reduce stock in real time)

- ERP/accounting system (e.g., for purchase orders and financial records)

- E-commerce platforms (e.g., to reflect stock availability across channels)

- Warehouse management solution (e.g., scanners, label printers, WMS modules)

- Suppliers (e.g., to automate reordering or sync delivery status)

- BI tools (e.g., for advanced reporting or predictive analytics)

This layer typically uses APIs, webhooks, or file-based sync methods like FTP or EDI.

Top features of inventory management software

Inventory management solutions are designed to help businesses efficiently track, control, and optimize their inventory levels across various locations. The key inventory management software features can vary depending on the specific requirements of the company. However, here are some of the most common and essential features:

Real time inventory tracking

Enables businesses to monitor stock levels in real time, track product movement, and manage inventory across multiple locations. This feature helps ensure accurate stock counts, reducing the risk of overstocking or stockouts.

Order management

Automates the process of order creation, tracking, and fulfillment. Order management features streamline procurement, sales order processing, and restocking, ensuring that inventory is replenished efficiently.

Barcode and QR code scanning

Supports the use of barcode or QR code scanning for easy data entry and inventory updates. This feature simplifies tasks like stocktaking, receiving shipments, and order picking, improving speed and accuracy.

Demand forecasting

Uses historical sales data and market trends to predict future inventory needs. This helps businesses plan ahead, maintain optimal stock levels, and reduce excess inventory while minimizing the risk of stockouts.

Automated replenishment

Automatically triggers reorder points when inventory falls below a predefined threshold. This ensures that stock levels are maintained without manual intervention, supporting timely restocking and reducing downtime.

Multi-location management

Allows businesses to manage inventory across various warehouses, stores, or distribution centers from a centralized system. This ensures consistency in inventory records and provides visibility across all locations.

Reporting and analytics

Provides detailed insights into inventory metrics such as turnover rates, stock levels, and order history. Customizable reports and dashboards help businesses identify trends and make data-driven decisions for inventory optimization.

Integration with other systems

Connects with other business software like ERP, accounting, POS, and e-commerce platforms, ensuring data consistency and supporting seamless workflows across the organization.

These features form the core functionalities of effective inventory management software, providing businesses with the tools to optimize inventory control, improve efficiency, and support growth.

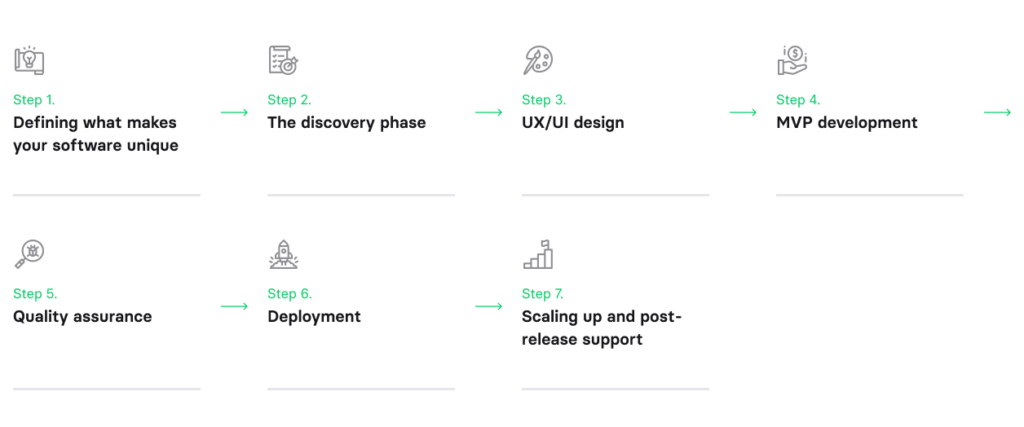

How to create inventory management software: step-by-step process

Developing robust inventory management software requires a meticulous approach to ensure it meets business needs and adapts to industry changes. At Volpis, our expertise in software development empowers us to deliver solutions that enhance efficiency and scalability. Here, we present a detailed walkthrough of the inventory system development process, from initial planning to successful deployment.

Step 1: Defining what makes your inventory management system unique

Before starting development, it’s crucial to identify what sets your inventory system apart. Your software team should analyze existing solutions to spot their flaws and gaps. From there, focus on creating features that address challenges specific to your industry.

Step 2: The discovery phase

The primary objective of the discovery phase is to gather all necessary information about the project. The goal is to create a clear project plan with requirements, a roadmap, and the best technologies to use. Key steps include:

- Analysis: Take a deep dive into your audience, competitors, and market trends to spot the features that will make your software shine.

- Identification: Pin down the key challenges and prioritize features that solve real problems.

- Wireframing: Sketch out how the software will look and flow, so you can tweak the design before building it.

- Technical analysis: Choose the right tools, mapping providers, and tech solutions to make sure the software is efficient, functional, and budget-friendly.

Step 3: UX/UI design

Once you know your software’s key features and who it’s for, it’s time to focus on UX/UI design. A good user experience (UX) and user interface (UI) are crucial for making the software effective and easy for people to use.

Step 4: MVP development

The minimum viable product (MVP) is a simple version of your software with the main features. It’s built to test and improve before creating the full version.

Step 5: Quality assurance

QA testing is super important to make sure the software works well, stays secure, and meets all standards. This step includes checking features, fixing bugs, and listening to user feedback. A solid QA process ensures your software is polished and ready to launch.

Step 6: Deployment

The deployment stage is when your software goes live. This step includes getting it ready for release, uploading it to platforms, and setting it up for users.

Step 7: Scaling up and post-release support

Once users start using the software, the development team works on improving its features, adding new ones, and reaching more users.We would be delighted to offer a free consultation to answer all your questions and address any inquiries you may have regarding the custom inventory management software development process. You can always contact us via info@volpis.com

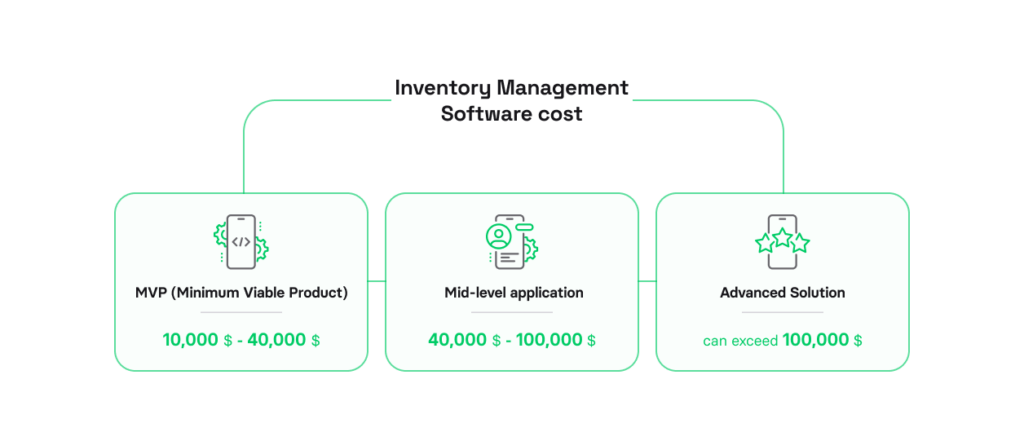

How much does inventory management software cost in 2026?

The cost of developing inventory management software can vary significantly based on the application’s features, complexity, and customization requirements. Here are some rough estimates based on typical development scenarios:

1. MVP (Minimum Viable Product)

A basic inventory management system with essential features, such as inventory tracking, order management, and basic reporting, can cost between $10,000 to $40,000 USD.

This version would typically include a simple user interface, real-time inventory updates, and basic integrations with existing systems. It’s suitable for startups or small businesses looking to automate fundamental inventory tasks.

2. Mid-level application

For a more sophisticated inventory management system that includes additional features like multi-location support, demand forecasting, barcode/QR code scanning, and integration with other business systems (e.g., ERP, e-commerce platforms), the cost could range from $40,000 to $100,000 USD.

This version is ideal for growing businesses that need more advanced capabilities and better scalability while still keeping development costs manageable.

3. Advanced solution

A highly advanced inventory management system, featuring AI-powered demand forecasting, predictive analytics, custom integrations with multiple systems (like WMS, accounting software, or CRM), real-time data visualization, and automated replenishment, can exceed $100,000 USD.

For large enterprises with complex inventory needs and specific industry requirements (such as perishable goods management or manufacturing), the development cost could reach $150,000 or more.

4. Additional cost considerations

- Integration costs: Custom integrations with existing systems can add to the overall cost, depending on the complexity and number of systems to be integrated.

- Maintenance and updates: Ongoing costs for software maintenance, bug fixing, and regular updates should also be considered, potentially adding 15-25% of the initial development cost annually.

- Licensing and third-party tools: If your custom inventory management solution requires third-party tools (e.g., cloud storage, advanced analytics software), licensing fees may apply, which can increase the total cost.

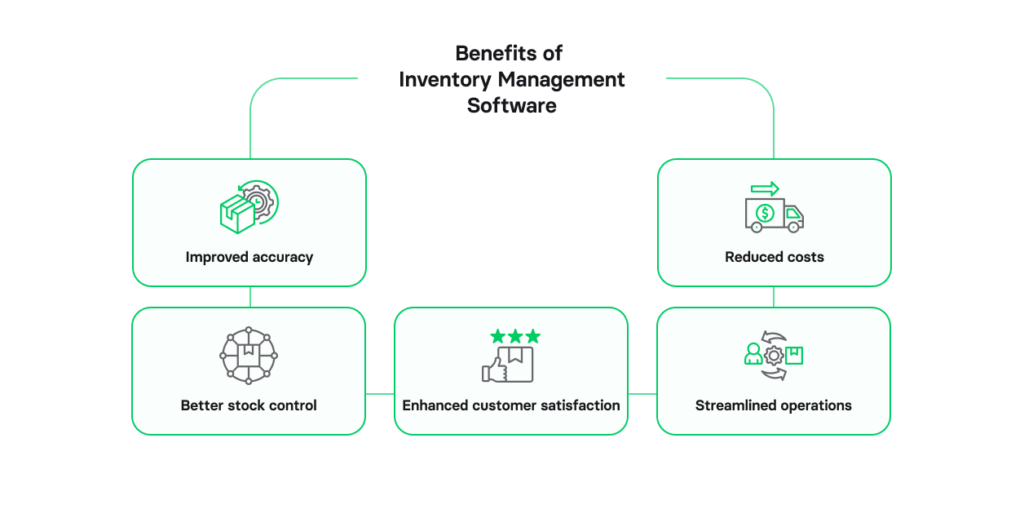

Benefits of inventory management software

Inventory management software is a transformative tool that has redefined the way businesses handle their inventory. By introducing automation and real-time analytics, it offers significant benefits across various aspects of business operations. Here, we provide an in-depth analysis of these benefits, establishing why contemporary businesses should consider implementing such inventory systems.

Benefit 1: Improved accuracy

One of the standout benefits of inventory management software is its ability to enhance inventory accuracy. By automating inventory management processes such as data entry and stock tracking, businesses can drastically reduce human errors. This accuracy ensures that the available inventory data reflects the actual stock levels, preventing discrepancies that can lead to stockouts or overstock situations. Accurate inventory data allows businesses to plan better and allocate resources more effectively.

Benefit 2: Better inventory control

Inventory management software provides businesses with greater control over their stock by offering insights into stock levels, movement, and demand patterns. This control helps in maintaining optimal stock levels, ensuring that businesses have the right products available at the right time. By avoiding excess stock and reducing stockouts, businesses can optimize their inventory holding and improve overall efficiency.

Benefit 3: Reduced costs

Implementing such a system can significantly reduce your inventory costs. By streamlining operations and automating manual tasks, businesses can lower labor costs and minimize wastage. Improved demand forecasting means less money is tied up in unsold stock, and lower storage costs can be achieved by maintaining lean inventory levels.

Benefit 4: Enhanced customer satisfaction

Customer satisfaction is at the core of successful business operations, and inventory management software contributes to this by ensuring products are available when customers need them. By avoiding stockouts and ensuring timely order fulfillment, businesses can meet customer expectations and improve service levels. Satisfied customers are more likely to return and recommend businesses to others, driving growth and profitability.

Benefit 5: Streamlined operations

Inventory management software streamlines operations by integrating various functions such as order management, warehousing, and shipping. This integration ensures smooth workflow across departments, reducing lead times and enhancing efficiency. Automation of routine tasks frees up valuable human resources, allowing them to focus on strategic initiatives that add value to the business.

The integration of inventory management software into business operations not only optimizes the inventory process but also contributes to significant operational efficiency and cost savings. By leveraging technology, businesses can improve accuracy, maintain better inventory control, reduce costs, and enhance customer satisfaction, ultimately leading to a more sustainable and profitable business model.

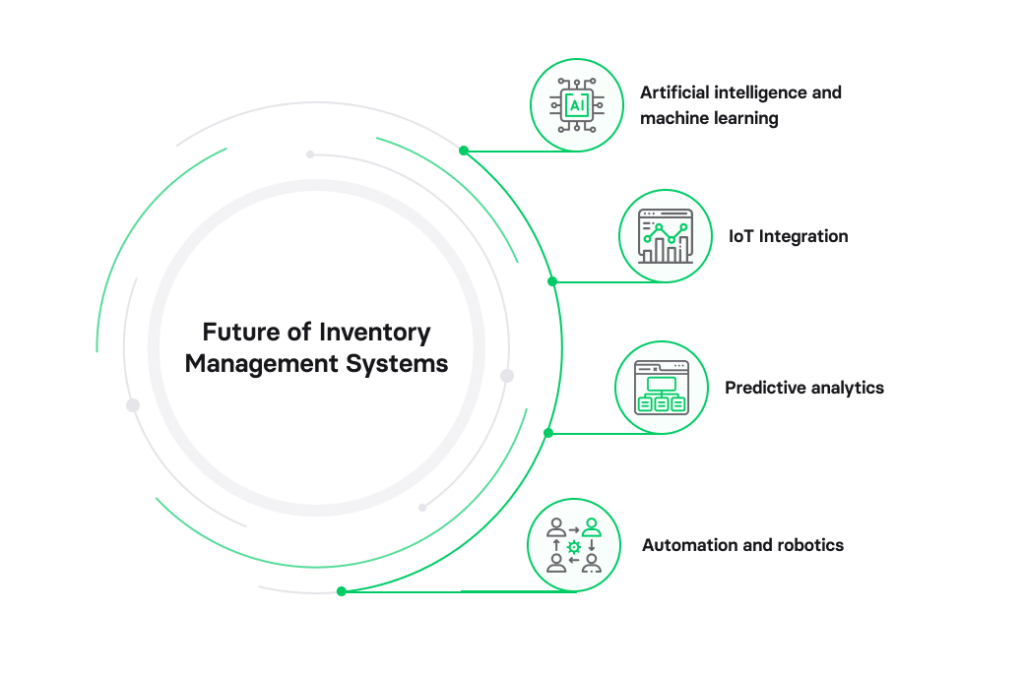

Future of inventory management systems: top trends of 2026

Here are the main trends of inventory management software, focusing on the integration of AI, IoT, and predictive analytics.

Trend 1: Artificial intelligence and machine learning

Artificial intelligence (AI) and machine learning (ML) are poised to become integral components of inventory management systems. AI can enhance decision-making processes by providing deep insights through data analysis, automating complex tasks, and improving accuracy in demand forecasting. With AI, inventory systems can autonomously manage stock levels, predict demand fluctuations, and even identify potential supply chain disruptions before they occur.

Trend 2: IoT Integration

The Internet of Things (IoT) is reshaping inventory management by offering businesses real-time data collection and monitoring capabilities. IoT devices, such as smart sensors, provide continuous tracking of inventory conditions, ensuring optimal storage environments. This integration allows for automated inventory control, reducing human intervention and minimizing errors. The ability to track goods throughout the supply chain in real-time enables businesses to gain unparalleled insights and transparency.

Trend 3: Predictive analytics

Predictive analytics leverages historical data and machine learning algorithms to forecast future inventory needs accurately. By anticipating demand, businesses can optimize their stock levels, reduce excess inventory, and prevent stockouts. This foresight is invaluable for strategic inventory planning and maintaining a competitive edge in the market. Predictive analytics ensures that businesses are not caught off-guard by changes in demand, allowing for more agile supply chain management.

Trend 4: Automation and robotics

Automation and robotics are ushering in a new era of efficiency in inventory management. Automated warehouses equipped with robotic systems for picking, packing, and sorting items can operate around the clock, significantly boosting productivity. These systems integrate seamlessly with inventory management software to offer precise control over stock, reducing human labor costs and enhancing operational efficiency.

The future of inventory management systems lies in the seamless integration of these advanced technologies, paving the way for more intelligent, responsive, and efficient inventory operations. By embracing these trends, businesses can achieve greater resilience, agility, and competitive advantage in their inventory management strategies.

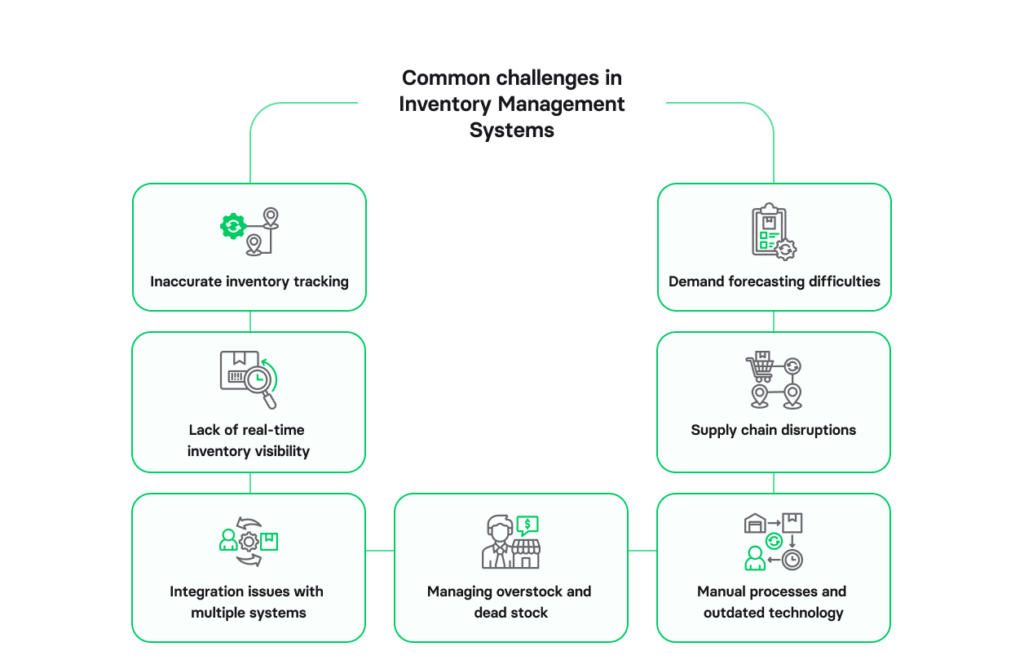

Common challenges in inventory management systems

Let’s take a look at the main challenges in inventory management systems:

1. Inaccurate inventory tracking

Maintaining precise inventory levels is crucial, yet many businesses struggle with tracking accuracy due to manual errors, outdated software, or fragmented systems. Inaccurate tracking can lead to stockouts, overstocking, or discrepancies between physical and recorded inventory, causing financial losses and operational disruptions. Addressing this issue often involves adopting more automated tracking solutions like RFID and barcode systems to reduce human error.

2. Demand forecasting difficulties

Predicting future inventory needs can be challenging, especially in dynamic markets where consumer demand fluctuates due to seasonal trends, market shifts, or external factors like economic conditions. Inaccurate demand forecasts often result in excess inventory or stockouts, impacting cash flow and storage costs. Implementing advanced analytics and AI-powered forecasting tools can help improve accuracy by analyzing historical sales data and market trends.

3. Lack of real-time inventory visibility

Real-time visibility is essential for managing stock across multiple locations, warehouses, or sales channels. Without up-to-date inventory data, businesses may face delays in order fulfillment, increased shipping costs, and customer dissatisfaction due to inaccurate availability information. Utilizing cloud-based inventory management systems that provide centralized, real-time data can help enhance visibility and ensure better decision-making.

4. Supply chain disruptions

Supply chain volatility, such as delays, shortages, or quality issues with suppliers, can significantly disrupt inventory management. This has become a critical challenge in recent years due to global events that affect logistics. Businesses need to adopt flexible inventory strategies, such as maintaining safety stock or working with multiple suppliers, to better manage disruptions and avoid costly delays.

5. Integration issues with multiple systems

Many businesses use a variety of systems for managing inventory, sales, accounting, and logistics, leading to potential integration challenges. Poorly integrated systems can result in data silos, inconsistencies, and inefficiencies that make inventory management more complicated. Solutions like enterprise resource planning (ERP) systems or application programming interfaces (APIs) can help centralize data and streamline integration.

6. Managing overstock and dead stock

Holding excess inventory ties up capital and incurs storage costs, while products that are no longer in demand become “dead stock” that is difficult to liquidate. Overstocking can also lead to inventory obsolescence, particularly for perishable or seasonal goods. Companies can address this issue by adopting just-in-time inventory practices, implementing stock rotation methods (like FIFO or FEFO), and using data-driven strategies to adjust reorder quantities.

7. Manual processes and outdated technology

Relying on manual inventory management processes or outdated technology increases the likelihood of errors and slows down operations. Many companies are hesitant to upgrade due to perceived costs or complexity, but automation can greatly enhance efficiency. Upgrading to modern, custom inventory management systems that offer automation and cloud capabilities can streamline operations and reduce manual workload.

Addressing these challenges requires a combination of strategic planning, technological adoption, and continuous process improvement to optimize inventory management and boost operational efficiency.

3 best inventory management software solutions of 2026

There are several successful inventory management solutions available today, including:

1) QuickBooks

QuickBooks helps you easily find products and services. You can track inventory flow, get alerts when it’s time to reorder and gain insights into your purchases and sales. It also lets you enter non-inventory items—products or services you buy and sell but don’t need to track as stock. Plus, you can create bundles by grouping multiple items or services together.

2) inFlow

inFlow simplifies inventory management. Whether you’re managing without a system, overwhelmed by spreadsheets, or frustrated with a costly ERP, inFlow has you covered.

3) Katana

Katana is a cloud-based inventory software that can help streamline your inventory management. It can help ensure on-time deliveries, accurate stock levels, asset tracking and effective supplier management.

Off-the-shelf vs custom-developed inventory management software

Choosing between off-the-shelf and custom-developed Inventory management software is a crucial decision for businesses aiming to optimize their inventory processes. Both options come with their own set of advantages and drawbacks. Here is a comprehensive comparison to help businesses make an informed choice that aligns with their strategic goals.

| Type | Advantages | Drawbacks |

| Off-the-shelf inventory management software solutions are pre-built software packages designed to cater to a broad range of industries and business sizes. | – Cost-effective: These solutions generally have lower upfront costs as development and testing have already been completed. – Quick deployment: Ready-to-use features allow for rapid implementation, enabling businesses to start managing their inventory processes immediately. – Established reliability: These solutions are often well-tested and updated regularly, ensuring stability and consistent performance. | – Limited customization: Off-the-shelf software may lack the flexibility to accommodate unique business processes or specific industry requirements. – Integration challenges: Compatibility issues can arise when integrating with existing systems, potentially leading to data silos. – Licensing costs: There may be ongoing licensing fees and constraints on scalability as the business grows. |

| Custom-developed inventory management software solutions are tailor-made to meet the specific needs of a business. | – Full customization: Custom-developed software is designed to fit seamlessly with a company’s existing processes and workflows, addressing their specific challenges and needs. – Scalability: As your business grows, the software can be adjusted and scaled to match the evolving demands and operational complexities. – Competitive advantage: Leveraging unique features and functionalities can differentiate your business in the market and enhance operational efficiency. | – Higher initial costs: Developing custom software requires a significant initial investment in terms of time and financial resources. – Development time: The process of building and testing custom solutions can be time-consuming, delaying full deployment. – Maintenance and updates: Custom solutions require ongoing maintenance and updates, which can incur additional costs and resource allocation. |

The decision between off-the-shelf and custom-developed inventory management software depends on a business’s specific needs, budget, and long-term strategy. Off-the-shelf solutions are suitable for businesses seeking quick implementation with standard features, while custom software is ideal for those requiring tailored functionalities and scalable options.

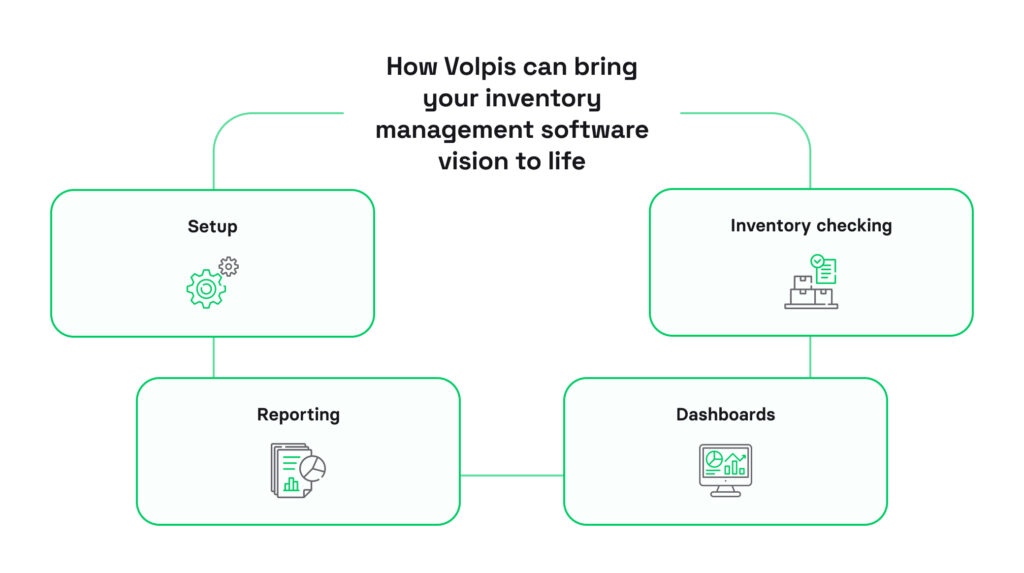

How Volpis can bring your inventory management software vision to life

Whether you’re looking to build inventory management software from scratch or incorporate new features into an existing system, Volpis stands ready to support you. Consistently recognized as one of the Top Custom Software Development Companies on Clutch, Volpis harnesses the power of technology to help business owners achieve remarkable milestones.

At Volpis, we have rich experience designing and developing inventory management modules and integrating them with warehouse management systems, including:

- Setup: Configuring key entities (Product, Product Category, etc.) and product handling strategies (FIFO, FEFO, LIFO), along with adding or importing products into the database.

- Reporting: Displaying stock levels and locations in reports, with features like filtering, sorting, exporting, data updates, and creating custom reports.

- Dashboards: Creating dashboards with key inventory-related metrics for easy monitoring.

- Inventory checking: Implementing inventory checks with barcode integration and mobile device support (Zebra mobile computers).

Our team brings extensive experience and creativity to each project. We invite you to explore our portfolio for a detailed look at the innovative software systems we have developed for our clients.

If you plan to develop inventory management software for your business, we would be happy to answer any questions you may have. You can reach out to us via info@volpis.com with any questions or to explore how we can be part of your journey.

FAQs

Can inventory management software integrate with my existing ERP system?

Yes, especially if you’re building a custom inventory management software. Integration with ERP systems like SAP or NetSuite is done via APIs or middleware. This ensures data consistency across accounting, procurement, and warehouse operations. Without integration, you’re stuck in silos, missing out on automation and real-time syncing.

What’s the best tech stack for developing an effective software inventory system?

A solid software inventory system in 2026 should be cloud-native, scalable, and modular. For example: React (frontend), Node.js or Python (backend), PostgreSQL or MongoDB (database), and AWS or GCP for deployment. GraphQL or REST APIs ensure clean integrations with WMS, ERP, and e-commerce platforms. This tech stack is future-proof and supports evolving features.

How can inventory software support global supply chain processes?

A good inventory management software solution must support multi-location tracking, time zones, languages, and tax structures. This enables real-time visibility across warehouses worldwide, automates compliance reporting, and syncs with localized delivery providers. It’s critical for CTOs looking to scale efficiently while maintaining operational control.

How do I estimate the ROI of inventory software before building it?

To assess ROI for inventory software development, track key metrics like stockout reduction, inventory turnover, labor hours saved, and fulfillment speed. Forecast your payback period based on time and cost savings. Custom dashboards and analytics make ROI visible and measurable, so you’re not guessing, you’re scaling smart.

Can inventory management software handle returns and reverse logistics?

Yes. Features in inventory management software systems can include return authorizations, automatic restocking workflows, and condition-based sorting. If returns are frequent, this module prevents inventory distortion and improves customer trust, especially important for e-commerce, retail, and service-based product flows.

How does inventory software help with sustainability goals?

A modern inventory management system software can track expiry dates, reduce dead stock, and lower emissions from overordering. Integrated reporting helps businesses monitor their environmental footprint — like packaging waste or temperature-sensitive goods — supporting ESG compliance and more responsible supply chain decisions.

Is off-the-shelf software enough, or should I build a custom inventory solution?

If you’re in a niche industry or scaling fast, custom inventory management software is a better choice. It aligns precisely with internal workflows, integrates with legacy tools, and evolves with your business. Off-the-shelf tools are quick to start but often require process compromises or third-party patching.