Do you need to eliminate inefficiencies in load planning, like wasted space, high costs, and missed deadlines? In this guide, you’ll learn all the ins and outs of load planning software development, helping you make informed decisions.

Manual load planning is time-consuming and inefficient, often leading to delays, resource mismanagement, and increased labor costs.

The solution? Load planning software.

By automating and optimizing load distribution, companies reduce costs, improve resource utilization, and maximize efficiency. In fact, the load planning systems market size is expected to reach nearly US $ 1555.7 Mn by 2029. Investing in the right software is no longer optional, it’s a competitive necessity.

In this article, you’ll learn:

- What load planning software is & how it works.

- How to develop a custom load planning solution for your company.

- How advanced algorithms and AI-driven tools streamline logistics.

- Key basic and advanced features to consider when developing a load planning application.

- How to choose between off-the-shelf options and custom load planning software development so that you could find the best solution for your business.

At Volpis, we have years of experience building custom load-planning software tools for businesses worldwide. If you have any questions about load planning optimization or the software development process, you can always connect with us via info@volpis.com

What is load planning software?

Load planning software is a logistics solution designed to optimize how goods are arranged within transportation vehicles, trucks, containers, railcars, or pallets, ensuring maximum space utilization and efficiency. By leveraging advanced algorithms, it creates optimized load plans that reduce empty space, lower transport costs, and minimize cargo damage.

Modern load planning software not only streamlines loading and unloading processes but also supports sustainability efforts by reducing the number of vehicles on the road, cutting fuel consumption, and lowering emissions. By integrating smart automation and real-time analytics, these tools help logistics providers enhance efficiency, improve profitability, and meet the rising expectations of customers and regulatory bodies alike.

Different industries benefit from load planning software in unique ways. Freight and logistics providers improve profitability by maximizing truckloads and reducing fuel costs. Retail and e-commerce businesses streamline order fulfillment and cut last-mile delivery expenses, while manufacturers optimize shipments and storage. In construction, the software ensures secure transport of oversized loads while meeting safety regulations. Warehouses benefit from optimized space utilization, improving distribution and shipment accuracy.

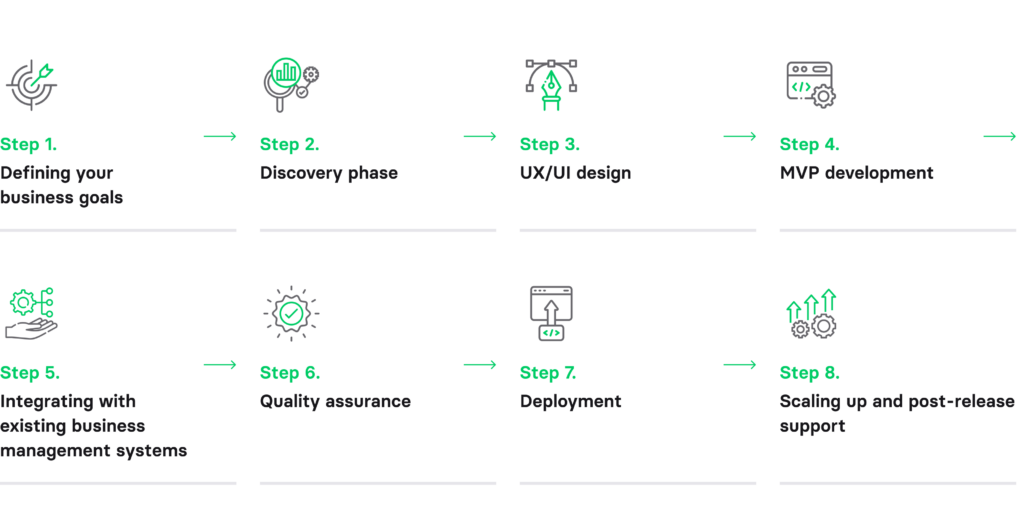

How to develop load planning software: proven step-by-step process

Let’s go through the steps to develop custom load planning software:

Step 1: Defining your business goals

Building an effective load optimization algorithm requires a deep understanding of your operations and goals. Whether you seek to maximize payload capacity, reduce fuel consumption, or automate load planning to minimize overhead costs, defining these requirements is crucial. A well-structured strategy enables the development team to create precise project specifications, select the right technology stack, and integrate features that best support your business objectives.

Step 2: Discovery phase

In the discovery phase, we gather key project details to create a solid development plan. We start with market analysis to identify must-have features, then pinpoint industry challenges to prioritize solutions. Next, we create wireframes to map out the software’s layout for a smooth user experience. Finally, we conduct a technical review to select the best technologies to ensure efficiency and cost-effectiveness.

Step 3: UX/UI design

With a clear understanding of your software’s features and target users, we move on to designing the user experience (UX) and user interface (UI). The UX/UI design has a huge influence on how easy and enjoyable the software is to use. A well-designed interface will not only make the software functional but also ensure users have a smooth experience.

Step 4: MVP development

The first version of your software called the Minimum Viable Product (MVP), includes the essential features needed for testing and feedback. The MVP is a basic version of your software, but it’s fully functional enough to refine and improve as you go along.

Step 5: Integrating with existing business management systems

Integration of the load planning software with existing business management solutions such as ERP, TMS, WMS, or other relevant platforms optimizes data exchange and reduces manual inefficiencies. Seamless integration improves overall operational performance by enabling real-time data synchronization.

Step 6: Quality assurance

Quality assurance (QA) testing ensures your software works as it should, is secure, and meets all necessary standards. This process includes testing all features, fixing any bugs, and gathering feedback from users. A thorough QA process makes sure your software is ready for a smooth release.

Thorough quality assurance (QA) testing is essential to ensure proper functionality, security, and compliance. This includes testing features, fixing bugs, and gathering user feedback. A rigorous QA process guarantees high-quality software ready for release.

Step 7: Deployment

The deployment phase is when your software is officially launched. This includes finalizing the setup and ensuring everything runs smoothly.

Step 8: Scaling up and post-release support

Once the software is accessible to users, the development team focuses on adding new features, improving performance, and expanding the user base. They also provide ongoing support to address any issues or concerns users may have.

If you plan to build load planning software, we would be happy to answer all your questions about the development process. You can always reach out to us via info@volpis.com

Basic and advanced features that could be included in your load planning software

When developing load planning software, businesses can choose from a range of features that cater to different operational needs. These features can be categorized as basic or advanced.

Basic features of load planning software

Basic features of load planning software focus on core functionalities that ensure efficient and safe cargo handling.

| Container capacity management | This feature helps determine the maximum weight and volume a container or trailer can hold. It prevents overloading and underutilization, allowing companies to maximize transport efficiency while ensuring safe and legal cargo distribution. |

Load optimization & sequence picking | Automated load optimization arranges cargo efficiently based on weight, dimensions, and delivery priorities. By sequencing the loading process, perishable or time-sensitive shipments are prioritized, while deliveries to the same drop-off point are grouped together. Providing loading personnel with step-by-step instructions further improves efficiency and reduces errors. |

| Restrictions management | Load planning software must address both regulatory and operational restrictions for smooth operations. Equipment restrictions involve considering the capacity and physical attributes of transport equipment, such as door type and compartment size. Product restrictions focus on the characteristics of the cargo, like size, weight, shape, and packaging, which affect how it’s handled. Regulatory compliance ensures the software meets safety standards, such as weight limits and proper handling of hazardous materials. Customer requirements involve specific preferences, like distributing cargo across multiple containers to reduce theft risk or avoiding incompatible goods, such as keeping food and chemicals separate. |

| Balance management | Proper weight distribution is essential for transportation safety. Balance management ensures that loads are evenly distributed across trailers and containers, minimizing the risk of cargo shifting and vehicle instability. |

| Manual adjustments | In cases where unique customer requests or specific loading requirements arise, manual adjustments allow users to fine-tune cargo placement, improve stability, and accommodate special handling needs. |

| 3D visualization | A 3D visualization tool provides a detailed representation of the load arrangement, helping users identify gaps, overhangs, or imbalances before loading begins. This enhances precision and ensures optimal cargo stability. While not traditionally considered a basic feature, it has become an essential tool for visualization and analysis, significantly improving load planning efficiency. |

Advanced features of load planning software

Advanced features build upon these basics, offering deeper insights and automation to further optimize operations. They enhance decision-making, improve tracking, and integrate seamlessly with other systems to boost overall efficiency.

| Reporting and analytics | Advanced reporting and analytics provide valuable insights through customizable reports and dashboards. Businesses can analyze load efficiency, cost savings, and delivery performance, enabling data-driven decisions that optimize operations and improve financial outcomes. |

| Real-time tracking | Real-time tracking provides end-to-end visibility into cargo movement and delivery efficiency. Live tracking updates offer insights into vehicle location, estimated arrival times, and potential delays, enabling proactive issue resolution. |

| Route planning and optimization | Automated route planning tools identify the most efficient delivery routes by considering factors like traffic, delivery windows, and road restrictions. Optimized routing reduces fuel consumption, shortens travel time, and minimizes operational costs. |

| System integrations | Depending on business needs, these advanced features can be incorporated into a custom-built solution or integrated with a load planning system via an application programming interface (API). Seamless integration with enterprise resource planning (ERP), logistics management systems (LMS), transportation management systems (TMS), or warehouse management systems (WMS) enhances workflow automation, reduces manual data entry, and minimizes errors. |

| Analytics and business intelligence | Connecting to business intelligence (BI) and analytics platforms further improves performance tracking by analyzing key logistics metrics, such as container utilization, load efficiency, and delivery impact. These data-driven insights support continuous supply chain optimization and more informed decision-making. |

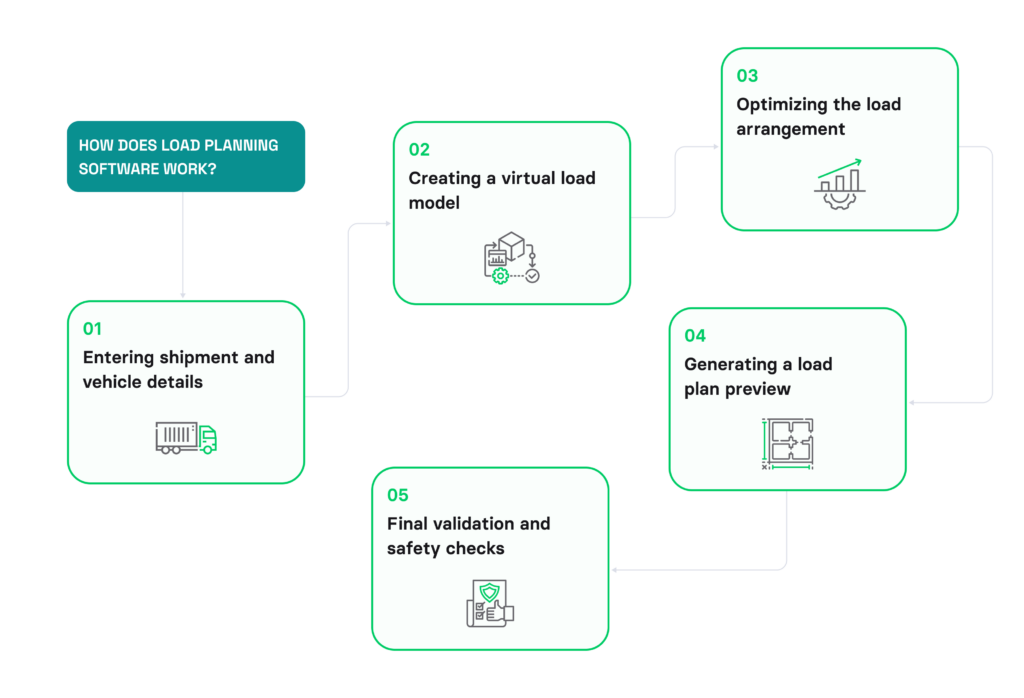

How does load planning software work?

Load planning software follows a structured process to optimize cargo arrangement and ensure safe, cost-effective transportation.

Step 1: Entering shipment and vehicle details

Users begin by inputting essential data about the goods, including their size, weight, and handling requirements. Information about the transport vehicle, such as its dimensions, capacity, and weight restrictions, is also provided.

Step 2: Creating a virtual load model

The software generates a 2D or 3D representation of the cargo inside the vehicle, factoring in critical constraints like weight distribution, center of gravity, fragile item placement, and hazardous material regulations to ensure compliance and stability.

Step 3: Optimizing the load arrangement

Advanced algorithms analyze multiple loading configurations to find the most efficient plan. The goal is to maximize available space, maintain cargo stability, and reduce empty areas within the vehicle.

Step 4: Generating a load plan preview

Once optimized, the software provides a detailed visual representation of the load arrangement, allowing users to review and make adjustments if needed.

Step 5: Final validation and safety checks

Before execution, the system verifies that the plan meets weight limits, balance requirements, and cargo protection measures, ensuring safe and damage-free transportation.

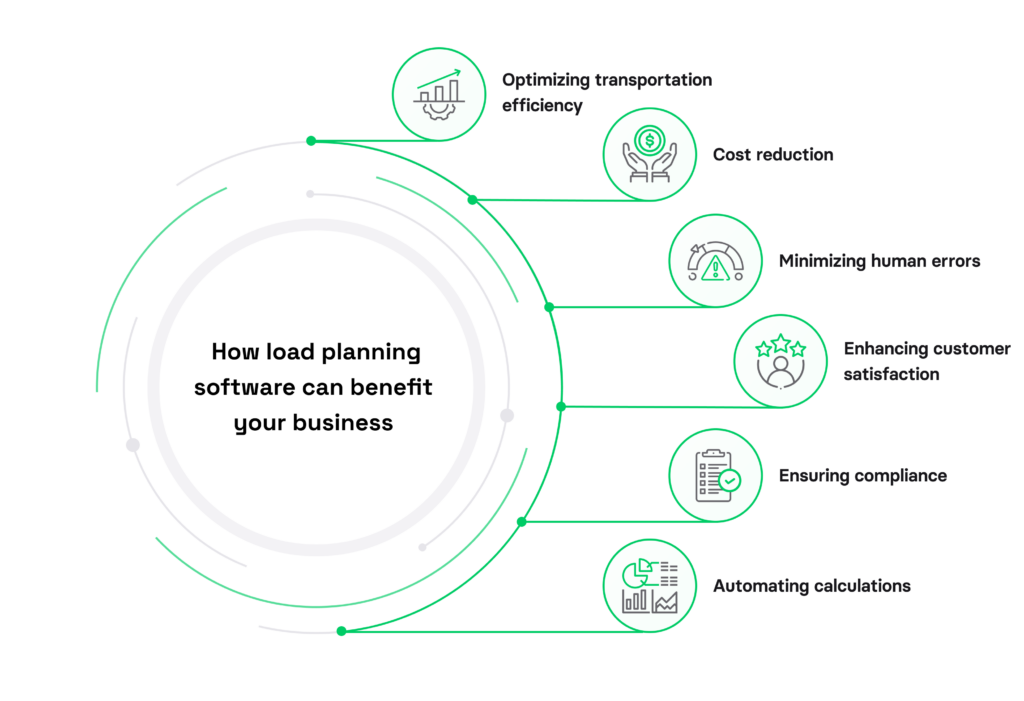

How load planning software can benefit your business

Load planning software plays a crucial role in helping businesses handle increasing shipment volumes, complex supply chains, and regulatory compliance while improving overall efficiency.

Optimizing transportation efficiency

At its core, load planning software enhances transportation efficiency by ensuring optimal space utilization, balanced weight distribution, and secure cargo placement. By automating the calculation of load configurations, companies can reduce empty space, minimize wasted capacity, and transport more goods using fewer vehicles.

Cost reduction

Effective load planning allows businesses to maximize the capacity of trucks, containers, and railcars, reducing the number of trips required for transportation. By ensuring full utilization of available space, companies save money on fuel, labor, and maintenance. Additionally, route optimization features in load planning software help reduce mileage and time on the road, further cutting costs.

Minimizing human errors

Manual load planning is prone to miscalculations, improper cargo placement, and inefficient use of space, leading to damaged goods, misplaced shipments, and increased operational costs. Automation reduces these risks by ensuring precise weight distribution, proper cargo sequencing, and compliance with regulatory requirements. This minimizes the need for costly corrections such as return trips, reloading, or re-routing shipments.

Enhancing customer satisfaction

Timely and accurate deliveries are critical for customer satisfaction. With load planning software, companies can provide more reliable delivery estimates, reduce delays, and ensure that shipments arrive in the correct order and condition. By streamlining logistics operations, businesses can build stronger relationships with customers and improve overall service quality.

Ensuring compliance

Transportation regulations impose strict limits on axle loads, vehicle capacity, and cargo security standards. Load planning software helps businesses stay compliant by automatically validating shipments against legal requirements, avoiding fines and penalties. Additionally, by maintaining proper weight distribution and securing cargo, the software reduces the risk of accidents and damage during transit.

Automating calculations

Load planning software allows businesses to quickly determine the best space utilization, making it easier to adapt to last-minute changes, urgent shipments, or unexpected disruptions.

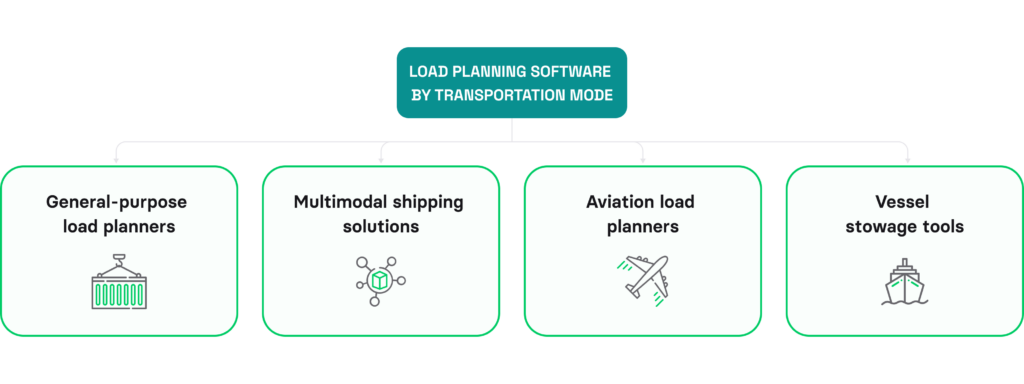

Types of load planning software

There are several types of load planning software, each designed to meet specific needs within the transportation and logistics industry.

Load planning software by transportation mode

Each transportation method presents its own set of challenges, which is why load planning solutions are tailored to meet specific needs for various industries and logistics operations.

1) General-purpose load planners

Most load planning tools focus on pallets, truck trailers, and standard shipping containers, offering solutions for land-based logistics.

2) Multimodal shipping solutions

Multimodal software supports various transportation methods (road, rail, sea, and air) and allows for seamless cargo transfers between modes.

3) Aviation load planners

Air transportation requires precise weight and balance calculations to ensure flight safety. Load planning software for aviation distributes cargo efficiently while accounting for aircraft center of gravity, crew weight, and passenger loads.

4) Vessel stowage tools

Ships transport diverse and oversized cargo, requiring specialized software to optimize stowage. Tools like AMT Marine Software offer load planning for general freight, roll-on/roll-off (RoRo) cargo, and oversized loads, ensuring space efficiency and safe transportation.

Load planning software by shipping method

Load planning software plays a key role in optimizing shipping efficiency, whether you’re transporting large or small shipments. The software ensures that cargo is arranged to maximize space utilization, minimize costs, and improve safety, regardless of the shipping method.

1) FCL/FTL (Full Container Load / Full Truck Load) shipping

FCL/FTL shipping involves dedicating an entire container or truck to a single shipment, making it ideal for large shipments that fully utilize capacity.

Load planning software helps optimize the use of available space, ensuring the load is packed securely and efficiently, reducing handling and transit time. This results in lower costs and faster deliveries for shipments that fill the truck or container completely.

However, when shipments do not fully utilize the space, load planning software ensures that it still provides an effective solution to minimize wasted space, though the cost per unit remains higher.

2) LCL/LTL (Less-than-Container Load / Less-than-Truckload) shipping

LCL/LTL is designed for smaller shipments that don’t fill an entire container or truck. The shipments of multiple shippers are consolidated into a single vehicle, making this method more affordable for businesses with lower shipping volumes.

Load planning software optimizes cargo consolidation, arranging multiple shipments to maximize space and minimize costs. The software also accounts for additional handling and the potential for longer transit times due to the need for consolidation and deconsolidation. While LCL/LTL is cost-effective, careful load planning is necessary to reduce the risk of damage and improve efficiency, ensuring cargo is securely loaded and distributed according to size, weight, and safety requirements.

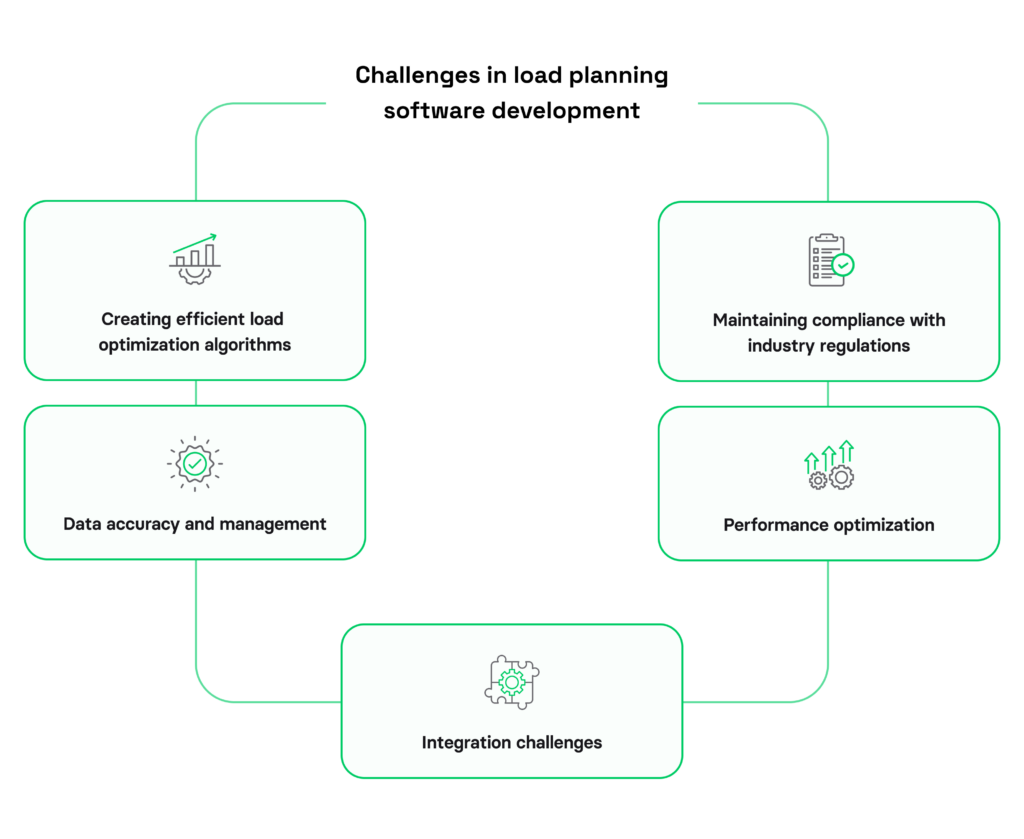

Challenges in load planning software development

Developing load planning software comes with its own set of unique challenges.

Creating efficient load optimization algorithms

Load planning software must handle multiple interdependent variables simultaneously. The system needs to consider cargo dimensions, weight distribution, vehicle capacity constraints, and stacking rules while maintaining optimal space utilization. Developing algorithms that can efficiently process these constraints while producing viable solutions in real-time presents a significant technical challenge.

Data accuracy and management

The accuracy of load plans depends heavily on input data quality. Developing robust validation mechanisms and maintaining data integrity across different sources presents an ongoing challenge. The system must handle inconsistent or missing data while still producing usable loading instructions.

Integration challenges

Modern supply chains require seamless data flow between different systems, like warehouse management systems, transportation management systems, and enterprise resource planning platforms. Ensuring reliable data exchange while maintaining system performance requires careful architectural decisions and robust error-handling mechanisms.

Performance optimization

Load planning calculations can be computationally intensive, especially when dealing with large data sets or complex constraints. Developing efficient algorithms that can provide solutions within acceptable timeframes while maintaining accuracy requires significant optimization effort and performance testing.

Maintaining compliance with industry regulations

Different regions and transportation modes have specific loading regulations and safety requirements. The software must incorporate these rules while remaining flexible enough to accommodate regulatory changes. This requires regular updates and careful validation of loading patterns against current compliance standards.

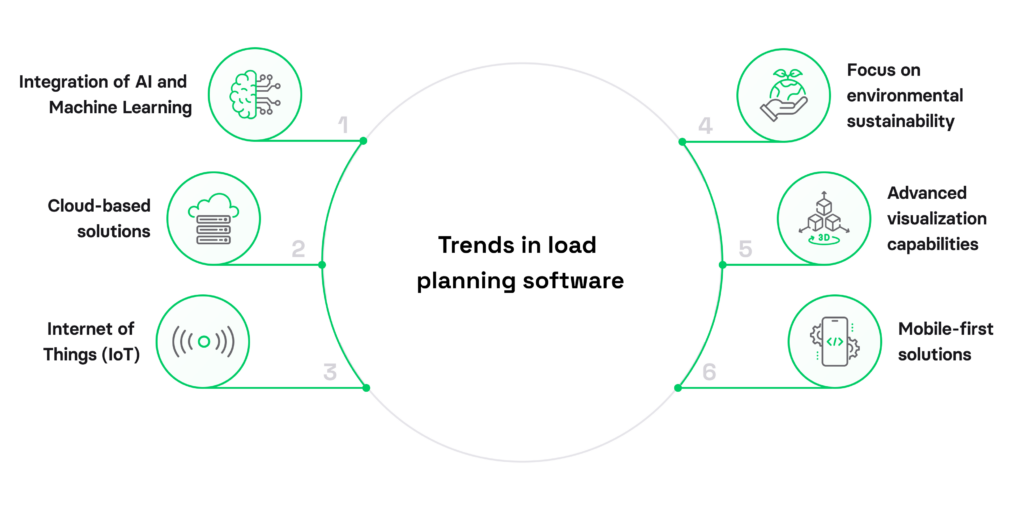

Trends in load planning software (2026)

These advancements are driven by cutting-edge technologies and new approaches that promise to enhance efficiency, sustainability, and collaboration across supply chains.

Trend 1: Integration of Artificial Intelligence (AI) and Machine Learning (ML)

Advanced AI algorithms are transforming load planning optimization by learning from historical loading patterns and real-time operational data. These systems can now predict optimal loading configurations while accounting for variables such as seasonal demand fluctuations and route-specific requirements. The software increasingly adapts to specific business patterns and improves its recommendations over time.

Trend 2: Cloud-based solutions

The movement toward cloud-based solutions enables better scalability and real-time collaboration. These platforms offer improved integration capabilities with other supply chain systems and support rapid deployment of updates and new features. The cloud infrastructure also facilitates better data sharing across different locations and stakeholders.

Trend 3: Internet of Things (IoT)

IoT sensors and connected devices are becoming integral to load planning systems. These technologies provide real-time data about cargo conditions, available space, and equipment status. The integration enables dynamic load plan adjustments based on actual conditions rather than theoretical calculations, significantly improving efficiency and reducing loading errors.

Trend 4: Focus on environmental sustainability

Environmental considerations are now a core component of load planning software. Modern systems incorporate carbon footprint calculations and suggest loading patterns that maximize fuel efficiency. They also factor in parameters such as recyclable packaging requirements and environmental regulations to support companies’ sustainability initiatives.

Trend 5: Advanced visualization capabilities

Three-dimensional visualization tools have become more sophisticated, offering detailed, interactive views of loading configurations. Augmented reality features are being integrated to assist loading personnel in executing complex loading patterns, reducing errors and training time while improving efficiency.

Trend 6: Mobile-first solutions

The shift toward mobile-centric operations continues to accelerate. Load planning software increasingly offers robust mobile interfaces that allow warehouse staff and drivers to access and modify loading plans from any location.

Top SaaS-based load planning software tools

Here are some of the top SaaS-based load-planning software options:

EasyCargo (General objective tool)

Image source: EasyCargo

EasyCargo is an online tool that simplifies the planning of truck and container loading. It offers 3D visualization, allowing users to optimize cargo placement, save space, and reduce transportation costs. The software is user-friendly and accessible via web browsers, eliminating the need for installation.

MercuryGate (Multimodal shipping)

Image source: MercuryGate

MercuryGate provides a comprehensive transportation management system (TMS) that supports multimodal shipping. It facilitates efficient load planning across various transportation modes, including road, rail, air, and sea, helping businesses streamline their logistics operations.

Cargospot Weight & Balance by CHAMP (Aviation load planner)

Image source: Cargospot Weight & Balance

Designed for the aviation industry, Cargospot Weight & Balance is a load planning tool that enhances the efficiency of aircraft loading. It automates load planning, optimizes aircraft performance, and ensures compliance with safety regulations by calculating weight distribution and center of gravity.

SimpleStow, AMT marine software (Vessel stowage tool)

Image source: SimpleStow

SimpleStow is a Windows-based application tailored for stowage planning of container vessels. It offers tools for effective cargo placement, reporting, documentation, and electronic data interchange, making it suitable for shipping lines, terminals, and marine professionals.

Videck® Stowage Planning (Vessel stowage planning software)

Image source: Videck® Stowage Planning

Videck® Stowage Planning is a software solution that allows users to visually place and plan cargo, group select, move, and align items. It aims to result in efficient and precise stowage planning, enhancing cargo handling processes.

Off-the-shelf vs custom load planning software development: choosing the best option for your business

When it comes to load planning software, businesses have two primary options: ready-made (off-the-shelf) solutions and custom-developed software. Here’s a detailed comparison of these two options to help you choose the best approach for your business.

| Factor | Off-the-shelf load planning software | Custom load planning software |

| Business requirements | Meets common industry needs, offering basic load optimization, standard reporting, and integration features. Works well for businesses with straightforward operations. | Can be tailored to unique business processes and specific cargo handling requirements, offering specialized features like custom loading rules and integration with legacy systems. |

| Cost implications | Lower upfront costs with predictable subscription fees. Ongoing updates and maintenance are vendor-managed. Suitable for small to medium-sized businesses. | Requires significant initial investment for development and ongoing maintenance. However, offers long-term value for businesses with unique needs that would otherwise need costly workarounds. |

| Implementation timeline and resources | Fast implementation (weeks rather than months) with established training and support. Suitable for businesses needing quick operational improvements. | Longer development cycles with more extensive testing and resources required for implementation, testing, and training. Takes more time to deliver value. |

| Scalability and adaptability | Predetermined scalability based on common growth patterns. May struggle with unexpected growth or unique requirements. | Fully customizable scalability, aligned with specific business strategies, offering greater flexibility for future growth and operational changes. |

| Integration capabilities | Standard integration options for common enterprise systems. May be insufficient for businesses with unique systems or complex data exchange needs. | Seamless integration with existing systems, regardless of complexity, making it ideal for organizations with specific data security or complex technology ecosystems. |

| Vendor relationship and support | Established support structures with limited influence over product development. | Greater control over the software’s evolution but requires managing relationships with development partners or internal teams. |

When selecting the right load planning software, it’s important to consider several key factors. Start by evaluating your budget, including both the initial investment and ongoing costs, to ensure it aligns with your financial capacity. Next, assess your timeline and determine how quickly you need to implement a solution.

Consider your specific business needs and how well they match the features offered by different software options. Be sure to evaluate your in-house technical expertise and whether you’ll need to hire external support for development or implementation. Finally, think about the scalability of the solution and how it will accommodate your business’s future growth.

Do you plan to develop load planning software for your business?

Whether you’re looking to build load planning software from scratch or enhance your existing logistics platform, Volpis is your trusted development partner. Consistently recognized as one of the Top Custom Software Development Companies on Clutch, Volpis harnesses the power of technology to help business owners achieve remarkable milestones.

We invite you to explore our portfolio for a detailed look at the innovative software systems we have developed for our clients.

Our team has successfully worked on load-planning solutions for our customers. In one recent project, we developed a load planning system for our U.S.-based partner. The solution leveraged advanced optimization algorithms to process multiple delivery parameters and generate optimal daily load distributions. It also featured intuitive manual override capabilities and sophisticated 3D visualization tools, enabling operators to fine-tune loading patterns as needed.

If you’re considering developing custom load planning software for your business, we would be happy to answer all your questions. You can reach out to us via info@volpis.com with any concerns or to explore how we can be part of your journey.

Let’s build your load planning software with a clear roadmap

We would be happy to answer all your questions and help make your project a total win!

FAQs

What is load planning software?

Load planning software is a tool designed to optimize the loading process of goods into transportation vehicles, such as trucks, ships, or containers. It helps businesses efficiently arrange cargo to maximize space utilization, reduce transportation costs, and ensure safe and compliant loading. By automating calculations and offering visualizations, load planning software helps streamline logistics operations and improve overall productivity.

What is loading planning?

Loading planning is the process of organizing and optimizing the arrangement of cargo into transportation vehicles or containers. The goal is to maximize available space, minimize damage, ensure safety, and adhere to regulations. This involves calculating weight distribution, stacking configurations, and the type of cargo to ensure an efficient and cost-effective transportation process.

What is the loading program in shipping?

The loading program in shipping refers to a detailed plan that outlines how goods will be loaded onto a ship or other transportation vessels. It includes the sequence of loading, the type of cargo, its position in the hold, and the weight distribution to ensure stability and safety during transit. This program is crucial for optimizing space and ensuring the ship’s compliance with international regulations.

How much does it cost to develop load planning software?

The cost of developing load planning software can vary widely based on factors such as features, complexity, and customization. On average, the development can range from $30,000 to $200,000, depending on the size of the project and the development team’s location. A basic version with essential features will be on the lower end, while a more complex, fully integrated system could be more expensive.

How long does it take to develop load planning software?

The time required to develop load planning software depends on the scope and complexity of the project. On average, it can take anywhere from 3 to 12 months to develop a fully functional load planning system. A simple system may take less time, while a more sophisticated solution with advanced features, integrations, and testing will require a longer development period.